In practical applications, the core performance of a UV LED water disinfection module lies in "flow rate matching". Mismatch between the module and system flow rate may reduce disinfection efficiency or cause overloaded operation of equipment, thereby affecting system safety and long-term reliability. This article provides systematic selection guidance from four aspects: the principle of flow rate matching, scenario-specific selection references, practical selection steps, and common misunderstandings.

The sterilization principle of UV LED relies on specific wavelength ultraviolet rays (mainstream 260–280 nm, corresponding to the absorption peak of microbial DNA) to destroy microbial genetic material. Its effectiveness depends on UV dose (unit: mJ/cm², equal to ultraviolet intensity × water retention time in the disinfection chamber). Flow rate directly affects the water’s retention time in the chamber, thus exerting a significant impact on disinfection efficiency and system stability.

Relationship Between Sterilization Efficiency and Flow Rate

Excessively high flow rate: Shortens the water’s retention time in the chamber, leading to insufficient UV dose, a significant drop in sterilization rate, and failure to effectively inhibit microbial proliferation.

Excessively low flow rate: Although it ensures UV dose, it easily causes increased system water pressure and poor water output (e.g., "flow interruption" in household water purifiers), affecting user experience and resulting in energy waste (the module still operates at high power under low flow).

System Design and Structural Compatibility

Different flow rate conditions require UV LED modules with corresponding power and chamber structures. Rational selection helps avoid unnecessary energy consumption and water pressure loss:

Even if the module power meets standards, poor matching between the chamber structure and target flow rate may lead to disinfection blind spots or hydraulic short circuits due to uneven flow field distribution, affecting overall disinfection consistency.

Long-Term Operational Reliability

The service life of UV LED modules is significantly affected by operating temperature and load intensity:

Long-term over-flow operation: To maintain sterilization effectiveness, the module may operate continuously at high load, causing temperature rise (the recommended operating temperature range for UV LEDs is -10~40℃), accelerating light degradation, and significantly shortening service life (e.g., from 30,000 hours to less than 15,000 hours).

2. Scenario-Specific Module Selection for Different Flow Rate Requirements

Application Scenario | Flow Rate | Features | Installation Location & Function |

Countertop water dispensers / Direct drinking fountains (point of use water filter) | 1–2 L/min | Compact size (fits countertop space), low noise, instant startup | Before the faucet / After the filter (end of the pipeline) – ensures terminal water safety |

Household water purifiers (RO systems, reverse osmosis water filter) | 2–4 L/min | Water pressure resistance (0.1–0.4 MPa), anti-scale | After the RO membrane (end of the pipeline) – prevents secondary pollution in water storage tanks |

Commercial water dispensers / Coffee machines | 4–10 L/min | High-frequency operation (8–12 hours daily), high-temperature resistance | Outlet of water tank / Before the heating device – avoids bacterial growth due to high temperature |

Commercial water purifiers (food service) | 10–20 L/min | Large pipe compatibility (DN20–DN32), impact water pressure resistance | End of the main pipeline – supports simultaneous water use by multiple people/devices |

Industrial / large-scale commercial water treatment (swimming pools, circulating water) | >20 L/min | Chemical corrosion resistance (e.g., chlorine in pool water), high flow uniformity | After the circulating water pump / Before water usage points – achieves reliable full-flow disinfection |

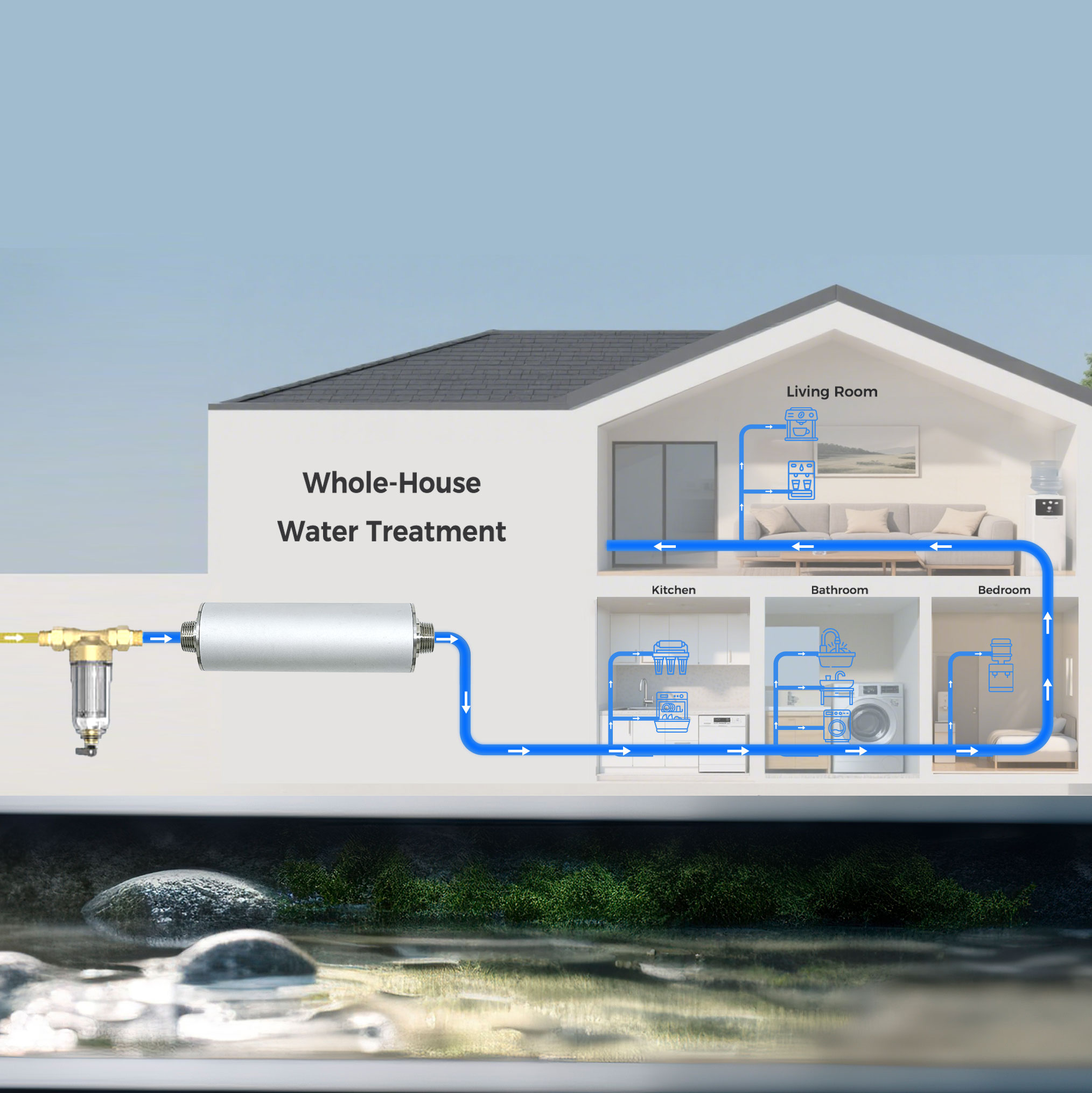

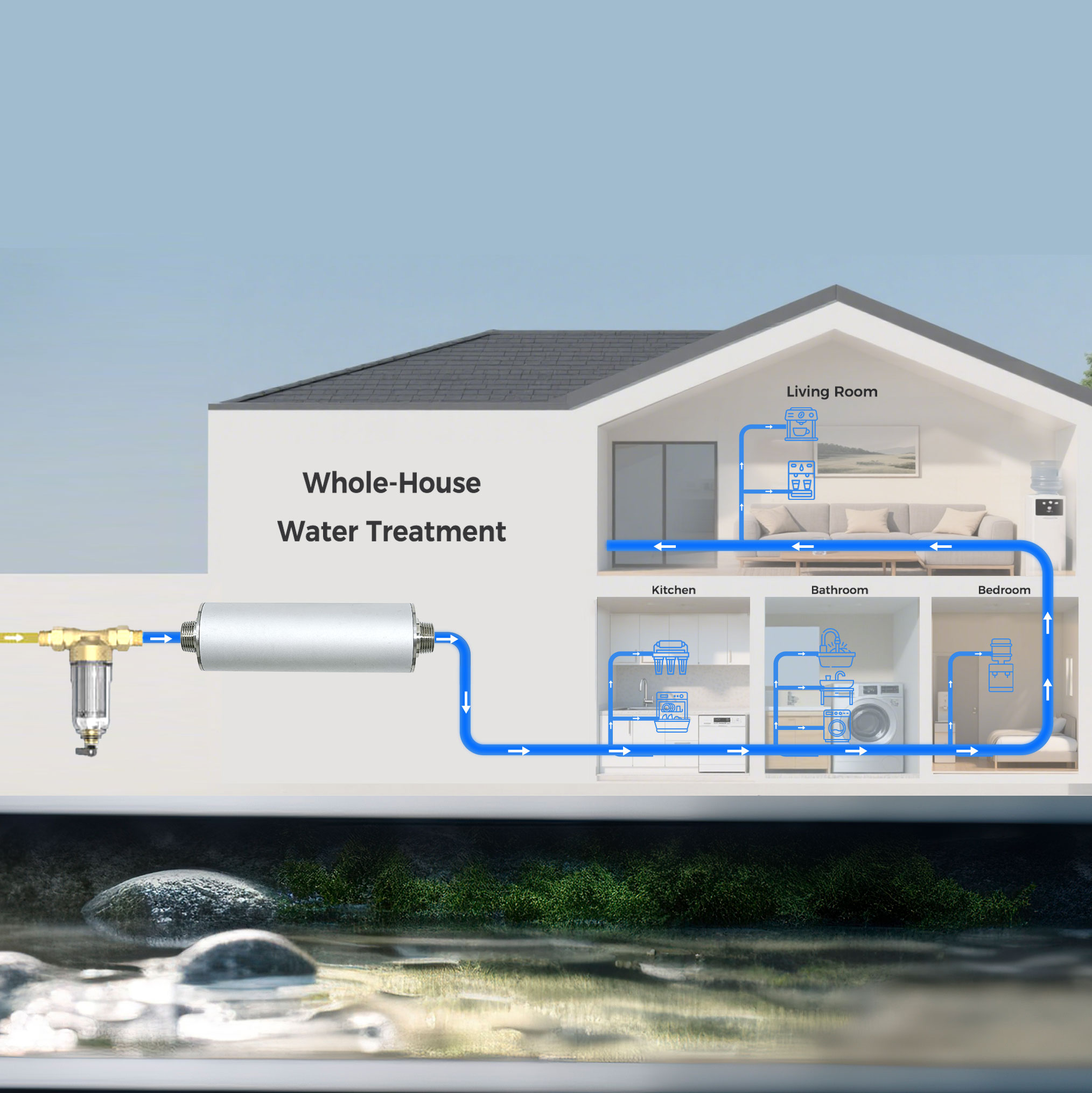

Whole home uv water filter systems | 8–15 L/min | Whole-house pipeline coverage, stable performance under variable flow | Main water inlet of the house – provides comprehensive UV water purification for all household water points |

Correction Factors to Consider During Selection

Point of Use Water Dispenser

Vending Machine for Water

Point of Use Reverse Osmosis System

Whole House Water Treatment Systems

3. Selection Steps and Recommendations

Step 1: Evaluate Actual Water Flow Rate

Household users: Calculate peak flow rate based on the number of simultaneously used devices (e.g., ro uv water purifier, point of use water filter) and their individual flow rates during peak usage hours.

Step 2: Select Matching Module Power and Chamber Configuration

Step 3: Consider Service Life and Maintenance Feasibility

Prioritize module models with excellent service life indicators and support for quick replacement to reduce downtime and maintenance burdens.

Step 4: Ensure System Integration Compatibility

Verify the physical and electrical compatibility between the module structure and existing pipelines/equipment. Ensure the UV LED module can be integrated into existing pipelines without major modifications, avoiding additional costs caused by retrofitting.

4. Common Selection Misunderstandings and Avoidance Methods

Common Misunderstanding | Consequences | Correct Practices |

Believing "the higher the power, the better" | Energy waste, accelerated cavity aging, and even water pressure issues | Accurately match power using flow rate formulas for UV water purification; avoid blind pursuit of high power. |

Focusing only on flow rate while ignoring water turbidity | UV light blocked by turbidity, leading to a sharp drop in sterilization efficiency | Test water turbidity first; add pre-filtration if turbidity > 5 NTU. |

Ignoring "installation location" | Poor UV effectiveness (e.g., installing before the filter, where turbidity affects performance) | For household/commercial use: Install "after the filter (end of pipeline)"; for industrial use: Install "after the pump, before water usage points". |

Neglecting "temperature impact" | High temperature (>40℃) accelerates UV LED light degradation | For high-temperature scenarios (e.g., coffee machines), select modules "with heat sinks". |

Conclusion

Flow rate matching of UV LED water disinfection modules is the key to achieving efficient and stable water treatment. Whether for household drinking water terminals, commercial water purification systems, or industrial circulating water treatment, rational module selection not only ensures disinfection effectiveness but also improves system energy efficiency, reduces maintenance costs, and extends service life.

For OEM manufacturers and integrators, scientific selection and system adaptation are the core of building high-quality UV water disinfection solutions. If you are seeking UV LED water disinfection modules suitable for different flow rate scenarios, please contact the professional team at MASSPHOTON to obtain customized selection plans and application support.

FAQ

Q: What is the relationship between the UV LED module flow rate and the required UV dose ($\text{mJ/cm}^2$)?

A: The flow rate directly determines the water's retention time within the disinfection chamber. To maintain the required UV Dose (e.g., $40\text{ mJ/cm}^2$), a higher flow rate necessitates a higher power UV LED module to compensate for the shorter exposure time.

Q: Is it always better to select a UV water module with the highest available power?

A: No. Oversized modules lead to energy waste, accelerated cavity aging, and potential hydraulic issues. Optimal selection requires accurately matching the module's power and chamber structure to your system's peak flow rate and UV transmittance level.

Q: How should UV LED modules be installed in RO systems or point-of-use water filters?

A: For residential/commercial applications, the module should always be installed after the final filter (at the end of the pipeline). This prevents secondary pollution and ensures the UV light is not blocked by high water turbidity.