I. Medical Scenarios

UVC LED Water Disinfection Modules are primarily used in the medical field for high-standard water purification, preventing hospital-acquired infections (HAI) and the transmission of opportunistic pathogens, such as Legionella and Pseudomonas aeruginosa.

Endoscope Reprocessing Water DisinfectionApplication

Application:

Integrated with fully automatic endoscope cleaning and disinfection machines to provide real-time disinfection of the final rinse water, preventing secondary contamination on the endoscope surface after cleaning.

Value Highlights:

Effectively avoids secondary contamination of the endoscope surface, significantly reducing the risk of healthcare-associated infections (HAI) caused by multidrug-resistant organisms.

Dental Clinics and Nursing FacilitiesApplication

Application:

Disinfection of dental unit waterlines (DUWL), shower water, and handwashing water to control microbial contamination in dental practices and long-term care facilities.

Value Highlights:

Significantly reduces the risk of pathogen transmission, enhancing safety for both patients and healthcare staff.

Hospital Water Systems Application

Application:

Implemented at point-of-use (POU) locations or as central water system disinfection to ensure the safety of drinking water and hot water systems throughout the hospital.

Value Highlights

Prevents infections caused by opportunistic waterborne pathogens such as Legionella and Pseudomonas aeruginosa.

Pure/Ultrapure Water Disinfection

Application:

Integrated into lab analyzers, endoscope reprocessing, dialysis units, and surgical instrument rinsing systems for terminal disinfection of bacteria, viruses, and protozoa.

Value Highlights:

Ensures microbial-safe water, reduces cross-contamination risks, and provides chemical-free alternative.

II. Commercial Scenarios

Efficient, compact, and sustainable UVC LED disinfection — the perfect mercury-free, chemical-free solution for commercial ultraviolet water treatment. Instant on, low energy, long-lasting performance.

Public Drinking Water Stations

Ice Maker (Built-in Refrigerator or Standalone)

Installed at the outlet end of public drinking water dispensers or stations in high-traffic locations such as airports, high-speed railway stations, shopping malls, schools, office buildings, scenic areas, etc., enabling real-time terminal disinfection for large flow rates (thousands of people per day).

Coffee Machine

Ensures drinking water safety for large-scale crowds, achieving a 5–6 log reduction in indicators such as Escherichia coli; significantly reduces the risk of secondary contamination in public facilities, improves overall urban public hygiene standards.

Community Water Vending Machines

Application:

Installed in the internal water pathway or outlet terminal of 24-hour self-service water vending machines in residential communities/neighborhoods, providing terminal disinfection for post-filtered water and/or recirculation disinfection for the storage tank.

Value Highlights:

Effectively addresses the “last meter” secondary contamination issue, ensuring safe self-service drinking water for residents; achieves 99.999% (5–6 log) pathogen inactivation rate.

Catering Industry Water Disinfection

Application:

Paired with ice makers, direct drinking water equipment, or coffee machine water lines for terminal real-time disinfection of beverage preparation water, ensuring sterile safety for milk tea, coffee, hand-shaken drinks, etc.

Value Highlights

Avoids chlorine residues affecting flavor: Unlike traditional chlorine disinfection, UVC does not alter water taste, preserving original flavors of beverages and enhancing customer satisfaction. Significantly reduces microbial contamination risks: 99.999% bacteria/virus removal rate, minimizing foodborne illness risks.

Central Kitchen

Application:

Integrated into the main water supply lines of large-scale central kitchens, vegetable washing machines, pre-processing water for ingredients, ice makers, and final rinsing systems for tableware, enabling real-time terminal and/or recirculation disinfection.

Value Highlights:

Prevents microbial cross-contamination, significantly reduces the total bacterial count on ingredients and tableware; replaces or substantially reduces chlorine disinfection, eliminating residual chlorine that affects the original flavor of ingredients and food safety.

Outdoor Atomization Systems

Application:

Integrated into high-pressure misting/cooling/humidification systems for outdoor restaurants, terraces, parks, amusement parks, or sports venues, providing terminal disinfection of the water supply to prevent the aerosol transmission of pathogens such as Legionella through misted water.

Value Highlights:

Effectively mitigates the risk of Legionella outbreaks (a common hazard in misting systems), delivers clean mist water with no chemical residues, enhances the safety and comfort of outdoor spaces, and is particularly suitable for high-temperature regions or large-scale event venues.

UV Sterilizers for Swimming Pools

Application:

Integrated into the circulation water system of swimming pools as an auxiliary disinfection module, used in combination with existing filtration systems (suitable for small to medium-sized commercial, hotel, community, or fitness center pools).

Value Highlights:

Effectively inhibits the growth of algae and bacteria, allowing a 30–70% reduction in chlorine usage (thereby significantly decreasing skin/eye irritation, chemical odors, and equipment corrosion); helps prevent waterborne infection risks, greatly enhancing swimmer comfort and overall experience.

III. Industrial Scenarios

Particularly suitable for industrial scenarios with stringent process water quality standards, high requirements for production continuity, and the need to enhance product quality and sustainability; supports real-time flow-through disinfection and modular embedded integration.

Food & Beverage Production Process Water Disinfection

Application:

Integrated into production water lines, ingredient water, CIP (Clean-in-Place) cleaning water, and workshop environmental water systems in beverage bottling lines, dairy processing plants, canning factories, and sauce/paste production facilities, enabling real-time terminal and/or recirculation disinfection.

Value Highlights:

Replaces chlorine disinfection to avoid residual chlorine affecting flavor, color, and shelf life; significantly reduces the risk of microbial exceedance, ensuring food safety and batch-to-batch consistency.

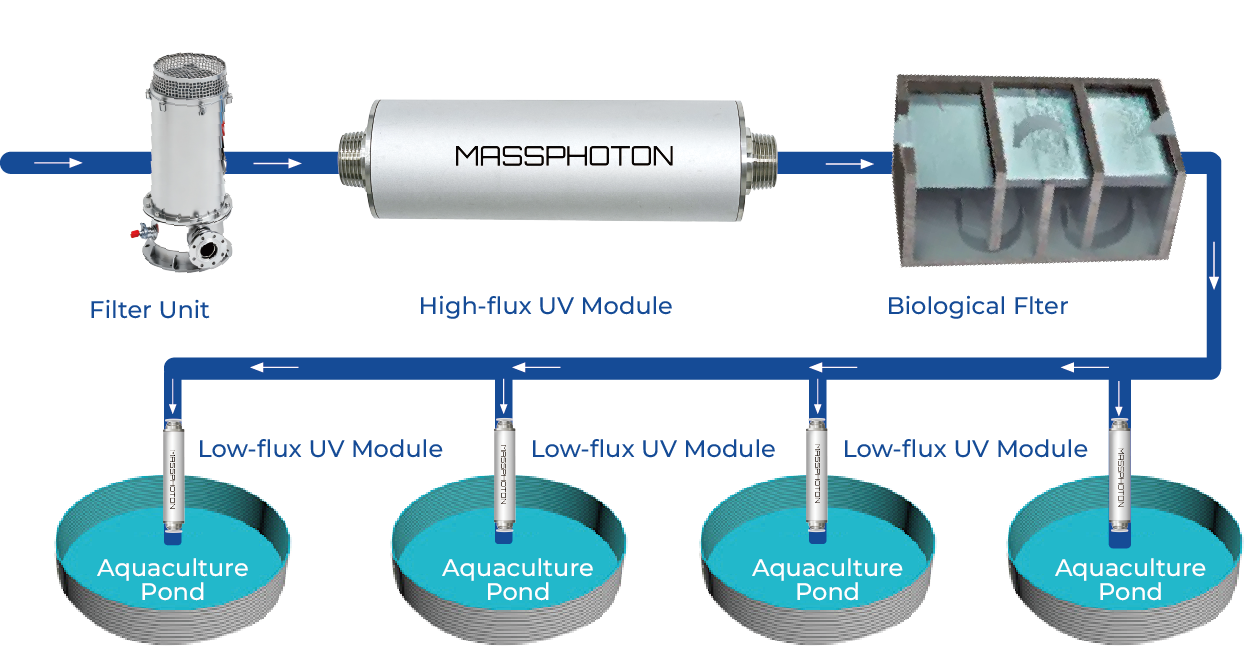

Aquaculture Recirculating Water Disinfection

Application:

Integrated into the recirculating water pipelines of factory-based Recirculating Aquaculture Systems (RAS), fish/shrimp/crab seedling workshops, and indoor high-density culture ponds, providing real-time terminal or recirculation disinfection to efficiently inactivate major pathogenic microorganisms such as Vibrio and Aeromonas species.

Value Highlights:

Significantly reduces disease incidence in fish and shrimp, improves survival rate and yield; decreases antibiotic usage, lowers drug residue risks, and enhances product export competitiveness.

UV Water Treatment for Poultry Farms

Application:

Integrated into poultry house (chicken, duck, goose, etc.) drinking water systems, including main inlet, branch lines to individual houses, and terminal drinkers, forming a multi-level real-time disinfection system (“main inlet → branch lines → terminal drinkers”) to kill pathogens such as Escherichia coli, Salmonella, and Campylobacter.

Value Highlights:

Removes biofilm from pipelines, improves poultry survival rate and immunity; zero drug residues, easily meets EU/Japan export standards; reduces maintenance and energy costs.

UV Water Disinfection System for Agriculture

Application:

Integrated into the water supply and recirculation systems of modern protected agriculture, including greenhouse hydroponics/aeroponics, soilless cultivation, drip irrigation, and sprinkler systems, providing terminal disinfection of irrigation water sources or nutrient solutions to inactivate root rot pathogens (e.g., Pythium, Fusarium), viruses, and other soil/water-borne pathogens; particularly suitable for reclaimed water reuse or high-turbidity sources.

Value Highlights:

Blocks the spread of waterborne diseases such as root rot and wilt, improving crop yield and quality; reduces chemical pesticide use, supporting green and sustainable agriculture; complies with reclaimed water irrigation standards, ensuring food safety; ideal for protected vegetables, flowers, and precision planting.

IV. Household Scenarios

Miniaturized, low-power design, perfectly embedded in household equipment.

Household Water Purifier Terminal Disinfection

Application:

As a terminal module for reverse osmosis (RO) water purifiers and ultrafiltration purifiers, the UVC LED is installed at the outlet faucet or post-filter stage to perform secondary disinfection on purified water, enhancing the safety of direct drinking water.

Value Highlights:

Secondary disinfection ensures direct drinking water safety: Effectively eliminates bacteria and viruses (e.g., 99.999% E. coli removal), solving secondary contamination issues in storage tanks or pipelines for fresh, worry-free water every time.

Desktop Water Purifier / Instant Hot Water Dispenser

Application:

UVC LED module is small in size and low in power consumption, perfectly integrated into the internal water path of desktop machines (e.g., after RO filter or before heating module), enabling real-time flowing water disinfection without additional storage space, supporting filter-and-drink-immediately and instant hot water.

Value Highlights:

Meets instant drinking needs: No waiting, one-touch hot/room temperature water, combined with UVC real-time disinfection for fresh, safe, bacteria-free water every time.

View Details

Whole House Water Treatment

Application:

The UVC LED water disinfection module is installed at the home's main water pipe entry (Point of Entry), Main pipe entry installation: Typically connected in series with pre-filters or central water softeners, placed after the main inlet valve, providing real-time flowing disinfection for whole-house incoming water, supporting high flow rates.

Value Highlights:

A modern replacement for mercury systems to protect against waterborne pathogens throughout the home.

Kitchen Appliances

Ice Maker (Built-in Refrigerator or Standalone)

Integrated into the ice maker's water supply pipeline or tank for terminal disinfection of incoming water, preventing bacterial growth in ice cubes (e.g., E. coli, mold).

Coffee Machine

Installed at the water tank outlet or internal pipelines for circulating/flowing disinfection of stored and brewing water, eliminating bacteria and biofilm in scale.

Dishwasher

Embedded in the water tank or rinse water circulation system to provide UVC disinfection for final rinse water, complementing high-temperature sterilization with broad-spectrum killing.

UVC LED Water Disinfection: Principles & Core Advantages

UVC LEDs emit light at 260–280 nm that directly damages the DNA and RNA of bacteria, viruses, and fungi, preventing replication and achieving ≥99.9% inactivation, including common pathogens such as E. coli, poliovirus, and Legionella. The process is chemical-free, instant on/off, and mercury-free.

High-efficacy disinfection

Achieves ≥99.999% inactivation of bacteria, viruses, and fungi within short exposure times—even under dynamic flows—surpassing legacy mercury UV and chlorination in many scenarios.

Eco-friendly, no residues

No chemicals added; no harmful disinfection by-products; avoids secondary contamination and aligns with health and sustainability goals.

Compact & easy integration

Small LED packages can be engineered into modules of various sizes to fit pipes and purifiers with minimal space and straightforward installation.

Smart Upgrades for Efficient Management

Water quality checks: Integrate basics such as temperature and TDS for quick visibility.

IoT remote management: Add connectivity for remote monitoring/control and smarter, more convenient water management.

Product Showcase

We not only offer a wide range of standard UVC LED disinfection modules, but also provide fully customized solutions tailored to your specific requirements. From flow rates and housing materials to integration form factors and smart control options, our engineering team works with you to design modules that perfectly fit your residential, commercial, or industrial applications.

Contact Us

Looking for a reliable UVC water disinfection module supplier?

Get in touch today for technical datasheets, pricing, and samples.

Why Choose Us for UVC LED Water Disinfection Solutions?

UVC LED water disinfection is a sustainable, scalable, and safe approach that ensures water quality with less space, lower energy use, and zero chemical residues. Whether you’re designing the next generation of household purifiers or upgrading commercial supply systems, UVC LEDs deliver the performance, flexibility, and environmental benefits modern users demand.

01

02

Innovative & Custom Solutions

We provide fully customizable modules for different flow rates, pipe sizes, and system requirements, enabling seamless integration into existing or new water systems.

03

Comprehensive Technical Support

From system design to installation and maintenance, our dedicated support team ensures smooth deployment and long-term performance for every client.

Why Custom Design

Every application has unique requirements — whether it’s a compact coffee machine, a high-flow commercial purifier, or a specialized industrial system. Standard modules may not always fit perfectly. That’s why we offer custom-designed UVC LED solutions to help OEMs and integrators achieve optimal performance and seamless integration.

Precise Flow Rate Matching

Ensure optimal disinfection performance by designing modules that align with your system’s specific flow capacity.

Seamless Appliance Integration

Customized form factors and housings make embedding into coffee machines, dispensers, and other appliances effortless.

Smart Control & Monitoring

Add IoT connectivity, auto on/off, or system feedback to fit advanced operational requirements.

Let’s Talk About Your Project

Looking for a reliable UVC water disinfection module supplier?

Get in touch today for technical datasheets, pricing, and samples.

Mob: +852 28918655

E-mail: info@massphoton.com