Key Challenges

Common Water Quality Challenges in Aquaculture

Pathogen Breeding and Outbreak Diseases

Untimely water exchange easily leads to excessive ammonia nitrogen and nitrite, providing breeding grounds for bacteria (Vibrio, Edwardsiella), viruses (IPN virus), parasites (myxobolus). Data shows Vibrio detection rate over 60% in untreated aquaculture water, causing shrimp "stealth death disease" and fish septicemia.

Biofilm Pollution in Recirculating Systems

Pipelines and filtration units in recirculating aquaculture systems easily form biofilms, blocking equipment and affecting flow while continuously releasing pathogens. Conventional chemical disinfection struggles to penetrate membrane structures, causing fluctuating effects.

Residue Risks of Chemical Disinfection

Traditional agents like chlorine disinfectants provide short-term bacteriostasis but disrupt water microecology, killing beneficial algae; drug residues enter the food chain via aquatic products.

Our UV Water Treatment Solution

Precise Deployment Plan Using UV-C Technology to Address Pain Points

Our UV (ultraviolet) systems use high-intensity UVC light to destroy the DNA and RNA of microorganisms, achieving near-complete inactivation without altering water chemistry. Ideal for Recirculating Aquaculture Systems (RAS), shrimp farms, hatcheries, and both freshwater and marine environments.

Installation of UV-C Unit at Water Inlet Point

Install medium-pressure UV-C units at farm inlets (post-water intake pumps) for effective UV water disinfection of external source water from rivers, lakes, or seas.

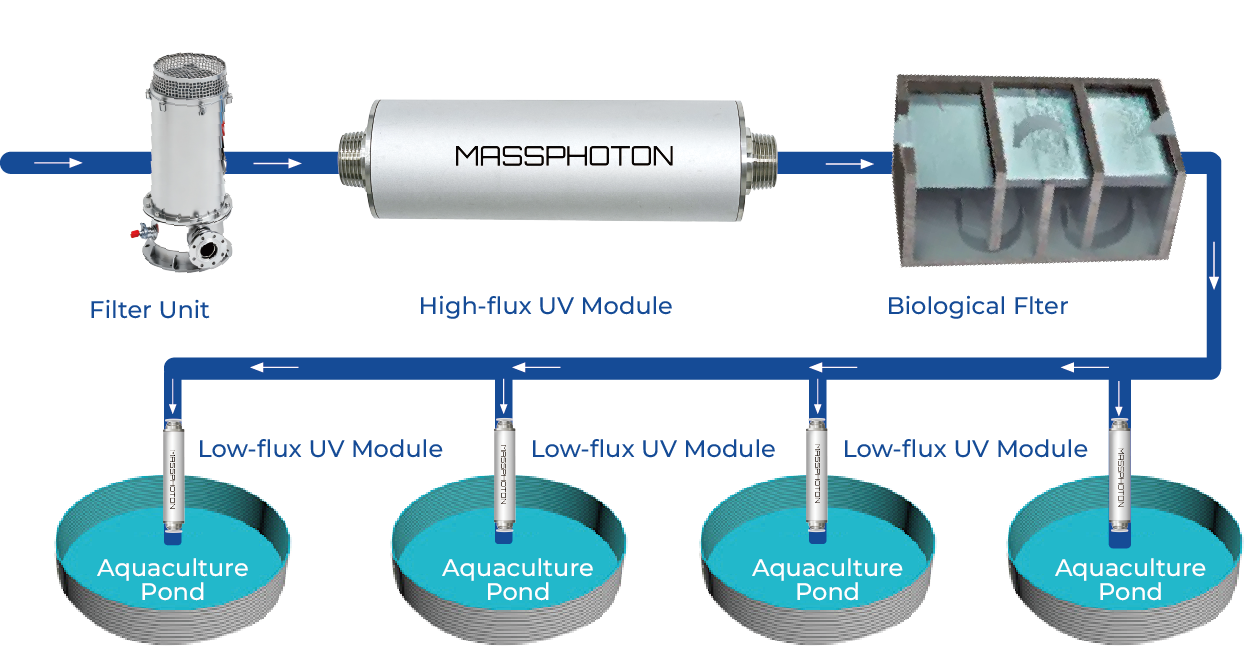

Deployment of UV Module in Circulating Water System

Deploy UV water disinfection modules after filtration units and before biofilters in recirculating systems. This ensures thorough aquaculture water treatment, eliminating pathogens before water re-enters culture tanks to prevent secondary contamination.

Benefits of Implementing UVC LED Technology

Synergistic Optimization of Safety, Efficiency, and Cost

Improved Fish & Shrimp Health

Cost Savings

Environmental Sustainability

Superior Water Quality

Versatile Application

Product Recommendations

The company possesses an experienced R&D team capable of designing and manufacturing precision screws of various specifications according to customer needs.

Keep in touch with us

Please fill out the form below or contact us through the following methods, and our professional team will provide you with personalized solutions and a detailed quotation.

Mob:+852 28918655

E-mail:info@massphoton.com