In recent years, ultraviolet (UV) water treatment has become one of the most popular chemical-free methods for disinfecting water. Homeowners, businesses, and municipalities are increasingly turning to UV systems for safe, effective pathogen control without altering taste, odor, or water chemistry. But what exactly does UV water treatment kill, and how reliable is it?

> Quick Summary: What does UV kill?

* Bacteria: E. coli, Salmonella, Legionella.

* Viruses: Norovirus, Rotavirus, SARS-CoV-2.

* Protozoa: Cryptosporidium, Giardia (Chlorine-resistant).

* Fungi: Aspergillus, Algae.

How UV Water Treatment Works?

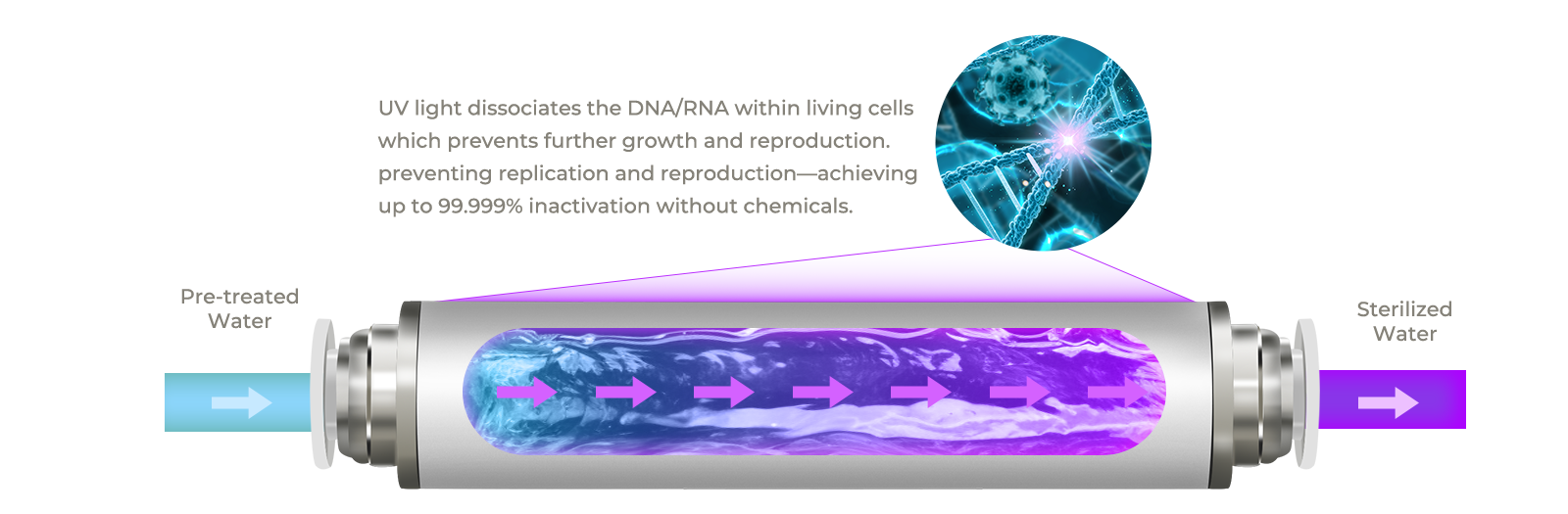

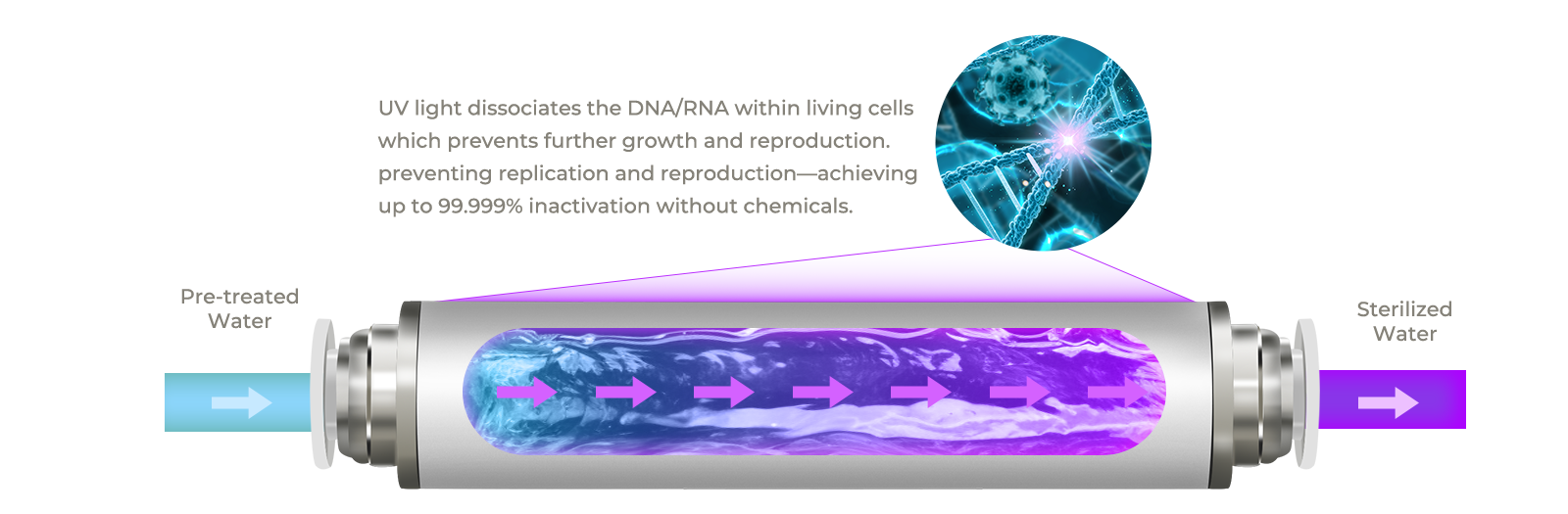

UV disinfection uses short-wavelength ultraviolet light—specifically UV-C light in the 200–280 nm range—to damage the DNA and RNA of microorganisms. When exposed to a sufficient dose of UV light (measured in mJ/cm²), these organisms lose their ability to reproduce and cause infection, effectively rendering them inactive or “dead” in terms of disease transmission.

Unlike chlorine or ozone, UV treatment does not add chemicals to the water and produces no harmful disinfection byproducts (DBPs). It is a physical process that works instantly as water flows past a UVC LED lamp inside a treatment chamber.

What Microorganisms Does UV Water Treatment Kill?

UV disinfection is highly effective against a broad spectrum of waterborne pathogens, including:

✅ 1. Bacteria

UV light can efficiently kill or inactivate a wide range of common waterborne bacteria, including:

Escherichia coli (E. coli) – A key indicator of fecal contamination

Salmonella spp. – Causes typhoid fever and foodborne illnesses

Legionella pneumophila – Responsible for Legionnaires’ disease

Pseudomonas aeruginosa – Common in hospital water systems

Shigella spp., Campylobacter, Vibrio cholerae, and more

These bacteria are typically inactivated with relatively low UV doses, usually between 5–15 mJ/cm².

✅ 2. Viruses

Viruses are generally more resistant than bacteria but are still highly vulnerable to UV-C radiation:

Rotavirus – A major cause of severe diarrhea in children

Norovirus – Extremely contagious and causes gastrointestinal illness

Hepatitis A Virus (HAV)

Adenovirus – More UV-resistant, but controllable with higher doses

Poliovirus, Enterovirus, and SARS-CoV-2 (COVID-19)

Viral inactivation typically requires 20–60 mJ/cm², depending on the virus strain.

✅ 3. Protozoa

UV treatment is especially effective against chlorine-resistant protozoa, such as:

Giardia lamblia

Cryptosporidium parvum

These parasites are notorious for causing severe gastrointestinal illness and are highly resistant to chlorine disinfection. UV, however, inactivates both Cryptosporidium and Giardia at relatively low doses (typically 10–20 mJ/cm² for 99.99% inactivation), making it one of the most effective treatments available.

✅ 4. Fungi and Algae

Though less frequently discussed, UV water treatment also helps control microbial regrowth in water storage and distribution systems:

Aspergillus spp. – A common fungal contaminant

Blue-green algae (cyanobacteria) – e.g., Microcystis aeruginosa, which can produce harmful toxins

Classified UV Irradiation Dosage Table (By Microorganism Type)

The following data is integrated from multiple authoritative sources, covering five major categories: bacteria (including spores), viruses, fungi, protozoa, and yeasts. It specifies the 90%/99% inactivation dosages (unit: μW·s/cm²), with special wavelengths noted separately.

1. Bacteria and Bacterial Spores (Highest Resistance, Highest Dosage Requirement)

| Microorganism Name | 90% Inactivation Dosage (μW·s/cm²) | 99% Inactivation Dosage (μW·s/cm²) | Notes (Resistance/Application Scenarios) |

| Bacillus anthracis | 4520 | 8700 | Pathogenic bacteria, common in biosecurity scenarios |

| Bacillus anthracis spores | 24320 | 46200 | Extremely resistant, requires ultra-high dosage (Consistent across Sources 2/3/5) |

| Bacillus subtilis | 5800 | 11000 | "Indicator organism" for disinfection efficacy verification |

| Bacillus subtilis spores | 11600 | 22000 | Common in environmental disinfection verification (Consistent across Sources 2/3/5) |

| Escherichia coli | 3000 | 6600 | Indicator of water pollution, low dosage requirement (Sources 2/3/5) |

| Salmonella spp. | 2140 (Typhoid fever type) - 8000 (Salmonella typhimurium type) | 4100 (Typhoid fever type) - 15200 (Salmonella typhimurium type) | Foodborne pathogenic bacteria, significant resistance differences among subtypes |

| Pseudomonas aeruginosa | 5500 | 10500 (Source 2) / 7600 (Source 3) | Common in hospital environments, note data discrepancies |

| Legionella pneumophila | 6050 | 12300 | Pathogenic bacteria in HVAC systems, dosage must match air flow conditions |

| Staphylococcus aureus | 2600 | 6600 | Skin/wound infecting bacteria, common in surface disinfection |

2. Viruses (Moderate Resistance, Dosage Requirement: 2000-240000 μW·s/cm²)

| Virus Name | 90% Inactivation Dosage (μW·s/cm²) | 99% Inactivation Dosage (μW·s/cm²) | Notes (Transmission Route/Sensitivity) |

| Poliovirus | 3150 | 6600 | Enterovirus, sensitive to UVC (Consistent across Sources 3/5) |

| Influenza virus | 3400 | 6600 | Respiratory virus, core target for air disinfection |

| Infectious hepatitis virus (e.g., HAV) | 5800 | 8000 | Waterborne virus, requires higher dosage than common bacteria |

| Tobacco mosaic virus (Plant virus) | 240000 | 440000 | Extremely resistant, for special scenario reference only (Sources 3/5) |

| SARS virus | - | - | Requires intensity > 90 μW/cm² for 30 minutes (CDC data, Source 4) |

3. Fungi (Molds) and Protozoa (Partially Chlorine-Resistant, UV Advantage Scenarios)

| Microorganism Type/Name | 90% Inactivation Dosage (μW·s/cm²) | 99% Inactivation Dosage (μW·s/cm²) | Notes (Application Scenarios/Chlorine Resistance) |

| Aspergillus flavus | 60000 | 99000 | Food spoilage fungus, requires high dosage (Sources 3/5) |

| Aspergillus niger strain | 132000 | 330000 | One of the most resistant fungi, common in humid environments |

| Chlorella vulgaris (Protozoa) | 13000 | 22000 | Water algae, affects water transparency |

| Nematode eggs (Protozoa) | 45000 | 92000 | Common in soil/sewage, higher resistance than common algae |

| Cryptosporidium (Associated with Source 1) | 10000-20000 (Converted from mJ/cm²) | - | Chlorine-resistant protozoa, UV is the preferred disinfection method; dosage requires 10-20 mJ/cm² (equivalent to 10000-20000 μW·s/cm²) |

4. Yeasts and Yeast Spores (Key for Food/Brewing Industry)

| Microorganism Name | 90% Inactivation Dosage (μW·s/cm²) | 99% Inactivation Dosage (μW·s/cm²) | Notes (Industry Applications) |

| Saccharomyces cerevisiae (Beer yeast) | 3300 | 6600 | Beer brewing disinfection, low dosage requirement |

| Saccharomyces cerevisiae (Wine/bread yeast) | 6000 | 13200 | Wine/bread industry, avoid affecting flavor |

| Yeast spores | 8000 | 17600 |

|

What UV Water Treatment Does NOT Effectively Kill

While UV is excellent against microorganisms, it has limitations:

Does not remove chemical contaminants (pesticides, heavy metals, pharmaceuticals, VOCs)

Does not remove particles or turbidity that can shield microbes from UV light

Has no residual disinfection effect—it only treats water at the point of application

Ineffective against bacterial spores or certain highly resistant forms (though these are rare in typical water sources)

For comprehensive water treatment, UV is often combined with filtration (to reduce turbidity) and other processes like reverse osmosis or activated carbon for chemical removal.

Why Choose UVC LED Water Treatment?

In 2025, UV-C LED technology has emerged as the superior choice for modern water disinfection — especially for homes, offices, point-of-use systems, and even emerging municipal applications. While traditional mercury lamp UV systems have served reliably for decades, UV-C LED offers a smarter, greener, and more convenient alternative.

Mercury-Free & Eco-Friendly: No toxic mercury — fully compliant with global environmental standards.

Instant On/Off: Activates in milliseconds — perfect for on-demand use with zero wait time.

Ultra-Long Lifespan: 15,000+ hours — almost no maintenance required.

Super Compact Design: Tiny modules fit anywhere: under-sink, countertop, RV, portable.

Superior Germicidal Power: Optimal wavelength delivers higher inactivation rates against bacteria, viruses & Cryptosporidium.

Conclusion

Ultraviolet water treatment is one of the most reliable and eco-friendly methods for eliminating harmful bacteria, viruses, and protozoan parasites—including chlorine-resistant threats like Cryptosporidium and Giardia—from drinking water. While it doesn’t address non-biological contaminants, it serves as an essential barrier in any multi-stage water purification system.

If you’re considering adding UV disinfection to your home or facility, ensure the system is properly sized, validated , and paired with pre-filtration for optimal performance.

Clean, safe water doesn’t have to come with chemicals. With UV treatment, it can be as simple as light.

Interested in learning more about UV systems for your home or business? Contact our water treatment experts today for a free consultation.

UV water treatment is quickly becoming the mainstream solution for next-generation water disinfection. It efficiently eliminates bacteria, viruses, protozoa, and algae without any additives, residues, or chemical pollutants. And with the advancement of UVC LED technology, UV systems are now more compact, efficient, and intelligent than ever—expanding their applications across residential, commercial, and industrial sectors.

Looking for a UV Water Treatment System Tailored to Your Needs?

Contact MASSPHOTON today.

We specialize in UVC LED water disinfection systems and integrated solutions, offering both standardized products and custom system design tailored to your specific application.

Whether you're a water purification equipment manufacturer, a system integrator, or a technology partner looking to upgrade existing systems, MASSPHOTON provides professional, efficient, and scalable solutions you can rely on.

Let's build a safer, smarter, and cleaner water future—together.