In the aquaculture industry, the timeless principle of “healthy fish start with healthy water” remains fundamental. Aquaculture water quality directly impacts the health, growth rate, and overall success of aquatic organisms. Traditional water treatment methods often rely on chemicals, raising concerns about drug residues, pathogen resistance, and environmental harm. Today, a safer, more efficient, and eco-friendly aquaculture solution is emerging as the new industry standard: UV water disinfection technology.

I. Why Aquaculture Farms Urgently Need UV Water Treatment Technology

Aquaculture is a high-density production system where harmful microorganisms—bacteria, viruses, fungi, and parasites—can rapidly proliferate in water. Outbreaks can devastate entire stocks, causing massive economic losses. Aquaculture UV sterilization offers a non-chemical solution with clear, compelling advantages:

High-Efficiency Broad-Spectrum Sterilization, No Chemical ResiduesUltraviolet light (especially the UVC band) instantly damages microbial DNA/RNA, preventing reproduction and inactivating pathogens. This process effectively targets nearly all aquatic pathogens, including bacteria, viruses, oocysts, and spores. Crucially, UV water disinfection adds no chemicals, leaving no harmful residues in water or farmed organisms—ensuring food safety for consumers.

Disease Prevention and Significantly Improved Survival RatesContinuous UV sterilization in aquaculture of incoming or recirculating water drastically reduces pathogen loads. This creates a robust “biosecurity barrier,” preventing outbreaks of common diseases like vibriosis and gill rot, thereby boosting survival rates of fry and adult stock.

Enhanced Farming Efficiency and Growth PerformanceHealthy aquatic animals have better appetites and higher feed conversion ratios. In a low-pathogen environment supported by UV aquaculture systems, organisms allocate more energy to growth rather than disease resistance—resulting in shorter cycles, higher yields, and improved ROI.

Improved Water Clarity and Algal Control in PondsUV light inactivates floating algal spores, helping prevent algae blooms in ponds and control excessive growth. This enhances water transparency, prevents “water blooms,” and creates a stable, visually appealing environment for aquatic life.

Eco-Friendly and Low Long-Term Operating CostsUV water disinfection systems produce no secondary pollution, making them ideal for eco-friendly aquaculture. While initial equipment investment is required, operational costs are primarily electricity-based. Compared to ongoing chemical purchases, UV systems offer superior long-term economics, simple maintenance, and extended service life.

II. Core Application Scenarios for UV Water Disinfectors

UV water disinfection is not a one-size-fits-all approach but is strategically deployed across critical aquaculture stages, primarily in three scenarios:

Inlet Water Pre-Treatment: For source water from rivers, lakes, or seawater, UV disinfection eliminates incoming pathogens (e.g., Vibrio spp.), viruses, and protozoa—preventing “external contamination” from entering recirculating aquaculture systems (RAS).

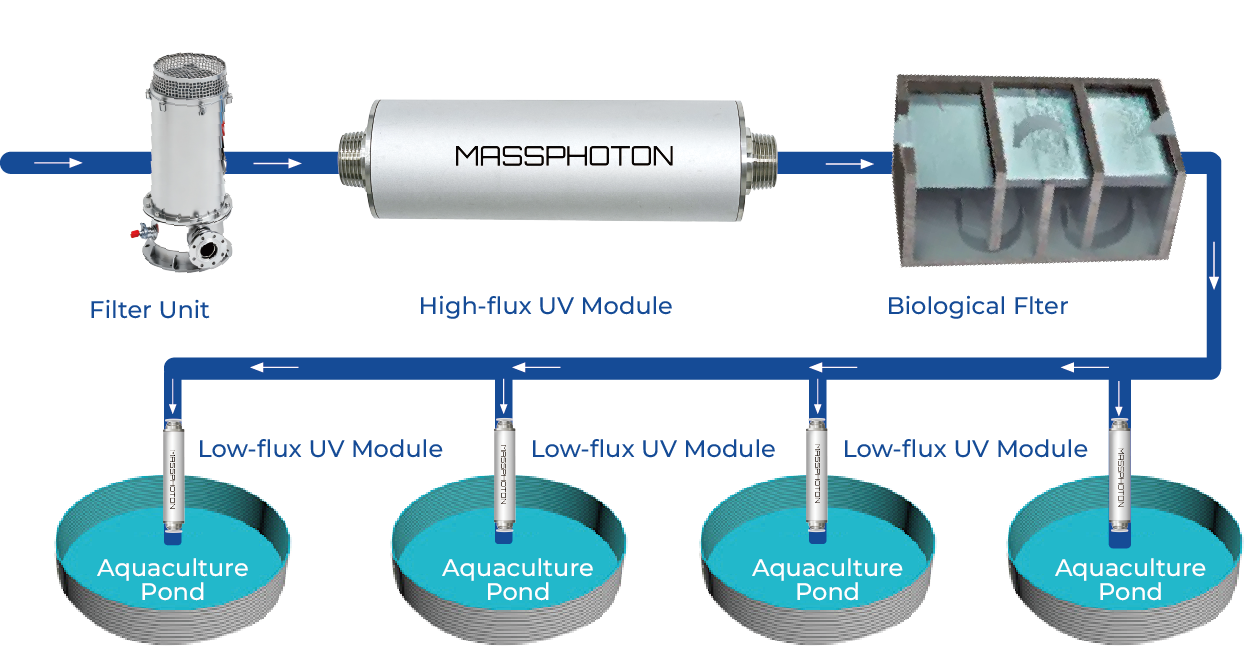

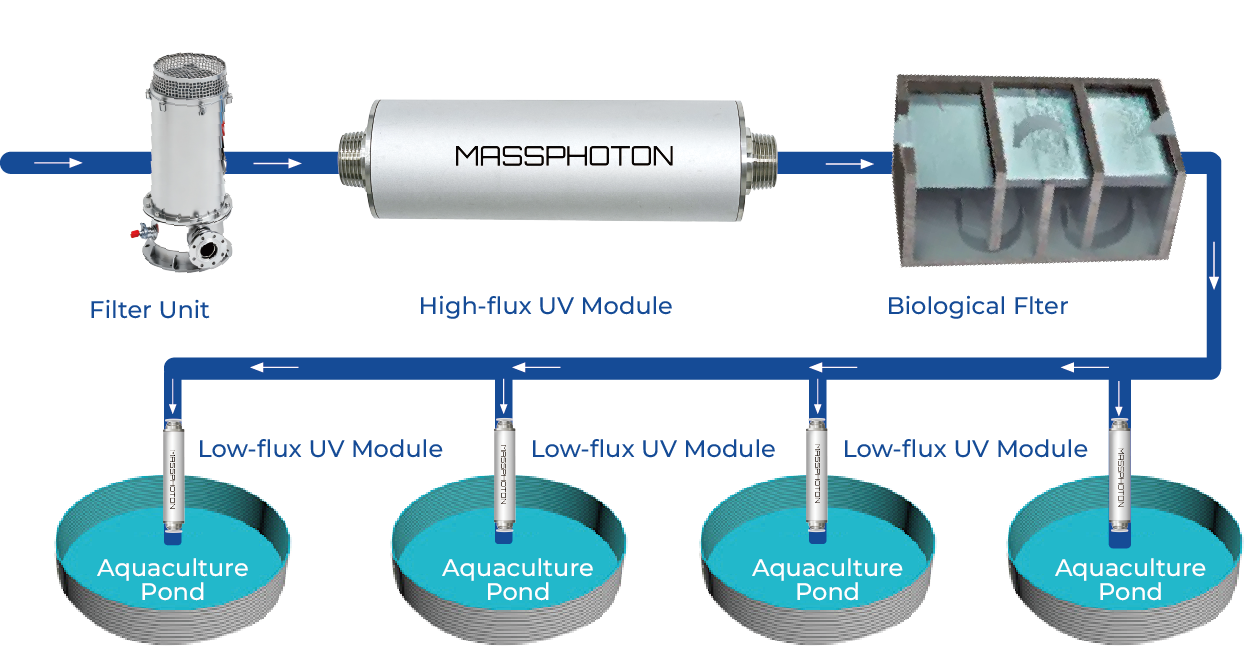

Recirculating Water System Treatment: In intensive RAS, water is reused continuously. UV units treat post-filtered and bio-purified water, eliminating pathogens generated during farming and maintaining microbial balance.

Tailwater Disinfection for Compliant Discharge: In regions requiring treated effluent, tailwater disinfection via UV replaces chemical agents, neutralizing harmful organisms without residual pollutants—protecting natural water bodies.

III. How UV Water Treatment Technology Specifically Improves Aquaculture Water Quality

Aquaculture water treatment with UV acts physically and directly on microorganisms. Though the principle is straightforward, its impact on water quality in fish farming is multi-dimensional and immediate:

Blocks Horizontal Pathogen TransmissionIn recirculating aquaculture systems, water reuse is a primary disease vector. UV disinfectors provide real-time treatment, completely interrupting pathogen spread via water media.

Strengthens Biosecurity for External Water SourcesUV pre-treatment of surface or groundwater inactivates unknown or targeted pathogens, preventing external invasions and establishing a secure defense for core production zones.

Optimizes RAS Operational EfficiencyIn intensive systems, UV units integrate with biofilters and protein skimmers. By controlling total microbial load, they reduce stress on downstream biological units, supporting stable microbial ecology.

Secures Success in Seedling and Hatchery StagesHatchery water is highly pathogen-sensitive. High-intensity UV aquaculture disinfection creates an ultra-low pathogen environment, critically improving fertilization rates, hatching success, and early larval survival.

Conclusion

Integrating UV water disinfection systems is a strategic choice for modern aquaculture enterprises to achieve precision management, ensure production safety, and enhance core competitiveness. This science-backed technology addresses aquaculture water quality challenges head-on, making it an essential tool for sustainable development and maximized economic returns in the industry.

For customized UV water disinfection solutions tailored to your farm—including algal control in ponds, how to prevent algae blooms in ponds, and how to treat algae bloom in pond—contact our expert team. We provide comprehensive technical support to help you achieve safer, more efficient, and sustainable aquaculture production goals.