Sterilization is a critical process used to eliminate harmful microorganisms such as bacteria, viruses, fungi, and spores from various environments. The purpose of a disinfection is straightforward yet vital: to create sterile conditions that prevent infections, contamination, and the spread of disease. Sterilization has been a foundational practice in healthcare, laboratory research, food safety, and numerous industrial applications. As technology advances, new sterilization methods have emerged, offering more efficient, safer, and environmentally friendly ways to maintain hygienic conditions.

One of the most innovative and effective sterilization tools available today is the UV-C air disinfection. Unlike traditional disinfection that focus on surfaces or objects, UV-C air disinfection target airborne pathogens, providing continuous disinfection of the indoor air we breathe.

[ View Our UV-C Air Sterilization Solutions ]

Core Purpose of Disinfection

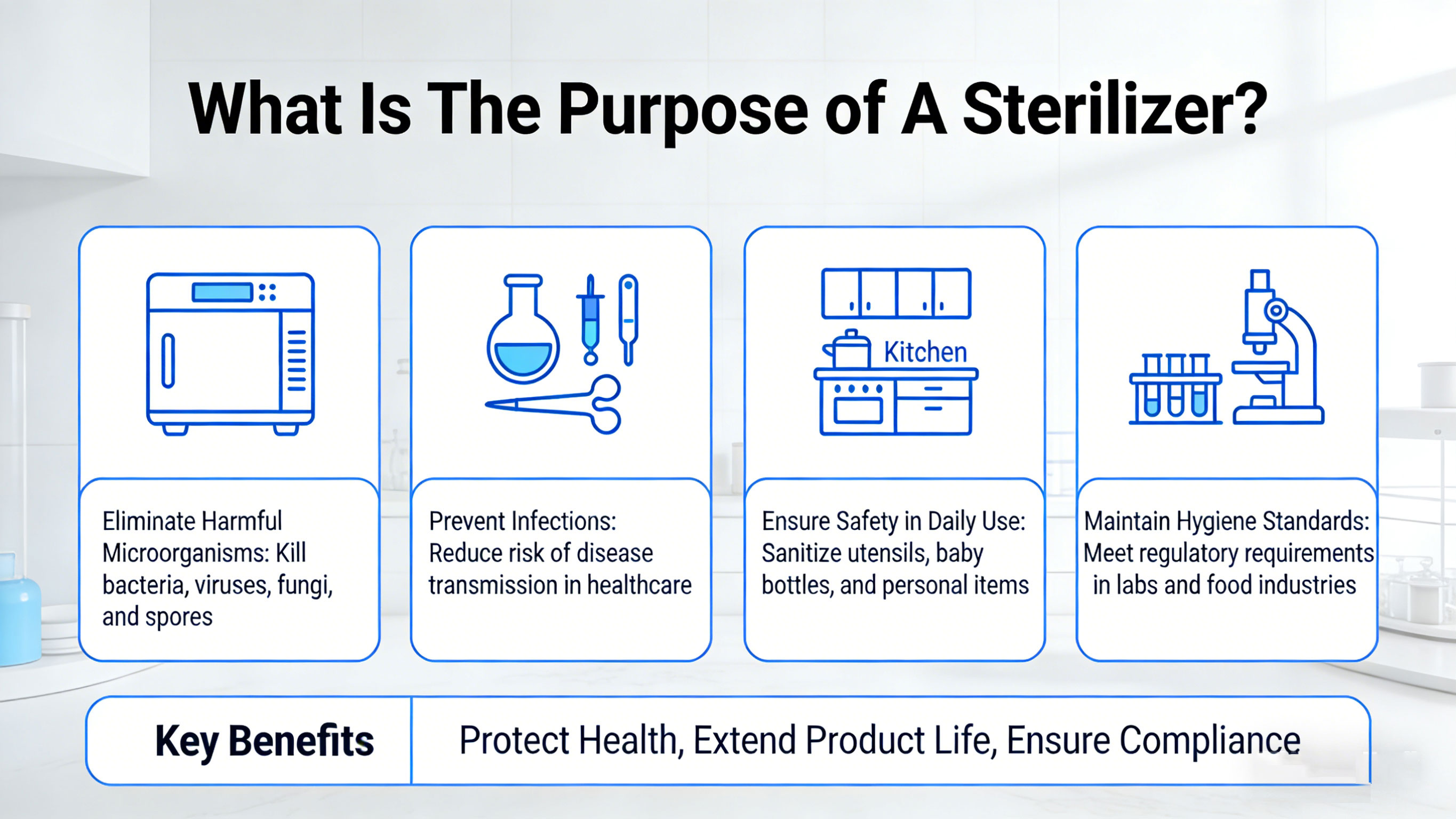

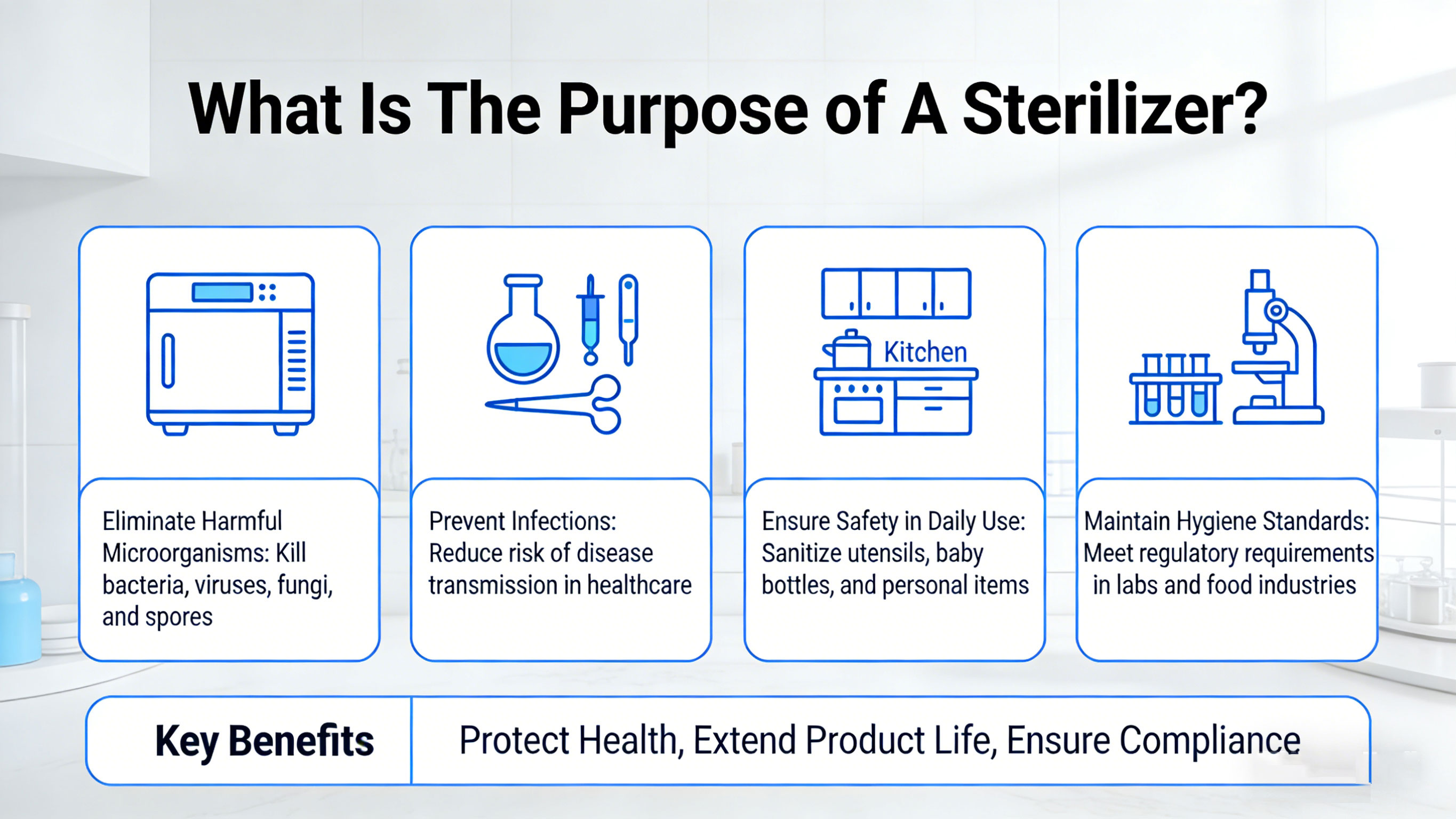

Disinfection is essential tool designed to eliminate or deactivate all forms of microbial life, including bacteria, viruses, fungi, mold spores, and even resilient bacterial endospores. Their primary purpose is to create safe, sterile environments that help protect human health, reduce contamination risks, and meet strict hygiene standards in various industries.

1. Elimination of Harmful Microorganisms

The foremost objective of any disinfection is to destroy dangerous microorganisms. Whether in the air, on surfaces, or within medical instruments, these microbes pose serious health risks. UV-C air disinfection, for example, use short-wavelength ultraviolet light (~275 nm) to disrupt the DNA and RNA of pathogens, rendering them unable to reproduce or cause infection. This level of microbial neutralization is far more effective than ordinary disinfection methods.

2. Prevention of Infection and Disease Transmission

Disinfection is critical in preventing the spread of infectious diseases. In healthcare environments, surgical instruments, isolation rooms, and even patient wards must be sterilized to stop pathogens from moving between patients or staff. UV-C air disinfection contributes by continuously purifying the air, reducing the risk of airborne disease transmission in crowded or high-risk areas.

3. Ensuring Sterile Environments

Maintaining a sterile environment is crucial in hospitals, laboratories, pharmaceutical production, and food processing facilities. In these settings, even minor microbial contamination can lead to severe consequences—ranging from patient infections to product recalls. Air sterilization systems, such as UV-C air disinfection, are increasingly used to support surface and equipment sterilization by ensuring that airborne contaminants are also neutralized.

Understanding the Distinction

It’s important to distinguish sterilization from other hygiene processes. Cleaning removes visible dirt, dust, and debris but does not necessarily eliminate pathogens. Disinfecting uses chemicals or heat to kill many germs but often falls short of full microbial eradication. Sterilization, by contrast, is the most comprehensive method—it destroys all forms of microbial life, ensuring the highest standard of hygiene.

In today’s health-conscious world, disinfection—especially UV-C-based technologies—are becoming central to infection control strategies across medical, commercial, and residential sectors. Their core purpose goes beyond routine cleaning: they provide an invisible shield of protection for people, processes, and products alike.

Types of Disinfection and Their Methods

Disinfection is designed using different technologies to achieve the same goal—eliminating or inactivating microorganisms that pose health risks. The method of sterilization often depends on the application, material compatibility, and environmental constraints. Here are the primary types of disinfection and the techniques they employ:

1. Heat-Based Disinfection

Autoclaves:

Autoclaves are one of the most widely used disinfection in hospitals, clinics, and laboratories. They utilize pressurized steam at temperatures around 121°C to 134°C to destroy all forms of microbial life, including spores. Autoclaves are highly effective for sterilizing surgical instruments, glassware, and other heat-tolerant items.

Dry Heat Disinfection:

Dry heat disinfection use hot air at temperatures between 160°C and 180°C, making them suitable for materials that cannot tolerate moisture, such as powders, metal tools, and oils. Though slower than steam sterilization, dry heat offers deep penetration and minimal corrosion risk.

2. Chemical Disinfection

Ethylene Oxide (EtO) Gas:

EtO sterilization involves exposing items to ethylene oxide gas, which is capable of penetrating porous materials and sealed packaging. It’s commonly used for delicate medical devices and instruments that cannot withstand high temperatures. However, strict control is needed due to its toxicity and flammability.

Hydrogen Peroxide Vapor (HPV):

HPV disinfection is increasingly used for room and equipment sterilization, especially in healthcare environments. The vapor effectively kills microorganisms and breaks down into harmless byproducts—water and oxygen—making it an eco-friendly option.

3. Radiation Disinfection

Gamma Rays and Electron Beams:

Used primarily in industrial settings, gamma rays and electron beams sterilize disposable medical equipment, food packaging, and pharmaceuticals. These methods offer deep penetration and high throughput, making them ideal for mass sterilization.

UV-C Light Disinfection:

UV-C sterilization uses ultraviolet light in the 200–280 nm range, specifically around 275 nm, to disrupt the DNA or RNA of pathogens, rendering them inactive. Unlike other methods, UV-C air disinfection is chemical-free, safe for continuous use in occupied spaces (when properly enclosed), and effective at maintaining air hygiene in real time.

Among all sterilization methods, UV-C air disinfection has become especially popular for air purification due to their convenience, speed, and ability to be integrated with HEPA and carbon filters for holistic disinfection.

The Role of UV-C Air Disinfection in Sterilization

UV-C air disinfection is device that use germicidal UV-C light, typically around 254-275 nanometers (nm), to disinfect the air by inactivating airborne pathogens. Unlike traditional disinfection that focus on surface or equipment sterilization, UV-C air disinfection provide a dynamic approach to maintaining air quality.

How UV-C Light Works to Sterilize Air?

UV-C light emits high-energy photons that penetrate the cell walls of bacteria, viruses, and fungi. This radiation damages the genetic material (DNA or RNA) inside the microorganisms, rendering them unable to reproduce or cause infection. This process, called germicidal irradiation, effectively neutralizes pathogens in the air.

What Is The Purpose of A Sterilizer in Modern Infection Control?

Sterilization is a critical process used to eliminate 100% of harmful microorganisms, including bacteria, viruses, fungi, and resilient spores. While the core purpose of a sterilizer is straightforward—to create a pathogen-free environment—the methods used to achieve this have evolved significantly.

In modern infection control, sterilization is no longer limited to surgical tools in an autoclave. As we spend 90% of our time indoors, the focus has shifted toward Air Sterilization. Airborne pathogens like Influenza, SARS-CoV-2, and Tuberculosis can linger in the air for hours, making traditional surface cleaning insufficient. This is where high-efficiency sterilizers, particularly UV-C technology, become the first line of defense in safeguarding public health.

Why UV-C Air Sterilizers are Replacing Traditional Methods?

For decades, facilities relied on chemical fogging and manual wiping. However, these traditional methods have clear limitations that UV-C Air Sterilizers effectively overcome:

Continuous Protection vs. Periodic Cleaning: Chemical disinfection only works at the moment of application. Once a person sneezes in a room, the air is contaminated again. UV-C air sterilizers operate 24/7, providing real-time, continuous disinfection while the room is occupied.

Zero Chemical Residue: Unlike ozone or chlorine-based systems, UV-C is a physical sterilization process. It leaves no toxic residue, no odors, and does not trigger respiratory issues, making it ideal for schools, hospitals, and offices.

Superior Efficacy on "Superbugs": Some bacteria develop resistance to chemical disinfectants. However, UV-C light (specifically at 254-275nm) physically destroys the DNA and RNA of pathogens, meaning microorganisms cannot develop "immunity" to it.

Lower Labor Costs: Manual sterilization is labor-intensive and prone to human error. A UV-C air sterilization system, once installed, requires minimal maintenance—usually just an annual lamp replacement.

Key Benefits of Using UV-C Sterilizers for Air Purification

Integrating a UV-C sterilizer into your environment offers more than just "clean air"—it provides measurable benefits for both health and operational efficiency:

Drastic Reduction in Cross-Infection:

By neutralizing 99.9% of airborne pathogens, UV-C sterilizers significantly lower the risk of disease transmission in high-traffic areas like waiting rooms, dental clinics, and open-plan offices.

Enhanced HEPA Filtration:

While standard air purifiers trap dust and pollen, they can become breeding grounds for bacteria on the filter surface. UV-C sterilizers actively kill the trapped microbes, ensuring the filtration system itself remains sterile.

Smart, Safe, and Silent:

Modern UV-C sterilizers, such as those developed by MASSPHOTON, feature enclosed designs that prevent UV leakage, ensuring they are 100% safe for use around people and pets. Their silent operation makes them perfect for classrooms and NICUs.

Air Sanitization vs. Surface Sterilization

While surface sterilization is essential in controlling direct contact transmission, airborne pathogens can linger in indoor air for hours. UV-C air disinfection continuously disinfect circulating air, reducing the risk of airborne disease transmission—a critical factor in enclosed environments such as hospitals, offices, schools, and public transport.

Advantages of UV-C Air Disinfection

Continuous Disinfection: They operate 24/7, providing ongoing protection.

Chemical-Free: UV-C sterilization avoids harmful residues.

Non-Intrusive: Silent operation and unobtrusive installation.

Complementary to Filtration: Often combined with HEPA and activated carbon filters for multi-layered air cleaning.

Many modern UV-C air disinfection is integrated into HVAC systems or designed as standalone units with smart features, enhancing their effectiveness in different settings.

[FAQ]

Q: What is the main purpose of a UV-C air sterilizer?

A: The primary purpose is to neutralize 99.9% of airborne pathogens, including viruses and bacteria, by disrupting their genetic material. This provides a continuous "invisible shield" in indoor environments.

Q: Is UV-C air sterilization safe for occupied rooms?

A: Yes. When using an enclosed UV-C air sterilizer (like MASSPHOTON’s units), the UV light is contained within a shielded chamber. This allows the air to be sterilized while people are safely working or resting in the same room.

Q: How often does a UV-C sterilizer need maintenance?

A: Most high-quality UV-C systems only require a lamp replacement every 9,000 to 12,000 hours (approximately once a year) and occasional filter checks, making them more cost-effective than continuous chemical supplies.

Conclusion: Choose the Science of Sterilization

UV-C air disinfection is a powerful solution for sterilizing indoor environments by inactivating airborne bacteria, viruses, and mold in real-time. Their integration of HEPA filtration, activated carbon, and germicidal UV-C light ensures comprehensive air purification, making them ideal for hospitals, offices, schools, and homes. As concerns about indoor air quality and airborne disease continue to grow, these systems offer a chemical-free, reliable way to protect occupant health.

If you’re exploring trusted solutions to enhance air hygiene, we recommend discovering MASSPHOTON LIMITED. Specializing in advanced UVC LED chip technology, MASSPHOTON develops high-efficiency UV-C air disinfection and disinfection systems engineered to safeguard human health. Their products feature long-lasting UV-C modules, smart automation, and energy-efficient designs tailored for critical environments like surgical suites, NICUs, and commercial spaces.

To learn how MASSPHOTON's cutting-edge technology can help you achieve safer, cleaner indoor air, visit their website or reach out to their expert team for custom solutions. MASSPHOTON delivers the science of disinfection—reliably and responsibly.

Ready to upgrade your air safety?

[Explore MASSPHOTON's UV-C Sterilization Solutions]

[contact our experts for a customized infection control plan.]