Eason Liao1[1] , Xiaoxiao Wang2[1], Qing Zhang[1], Jiancheng Wang[1], Shuzhong L[1]

1 MASSPHOTON LIMITED Hong Kong, China, HK1100

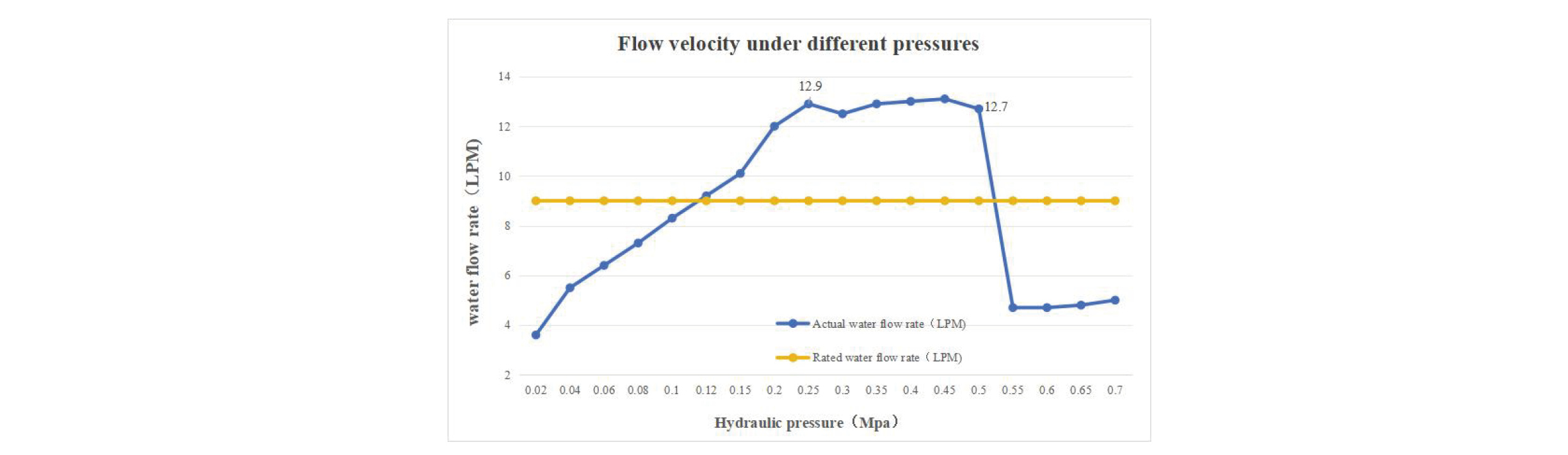

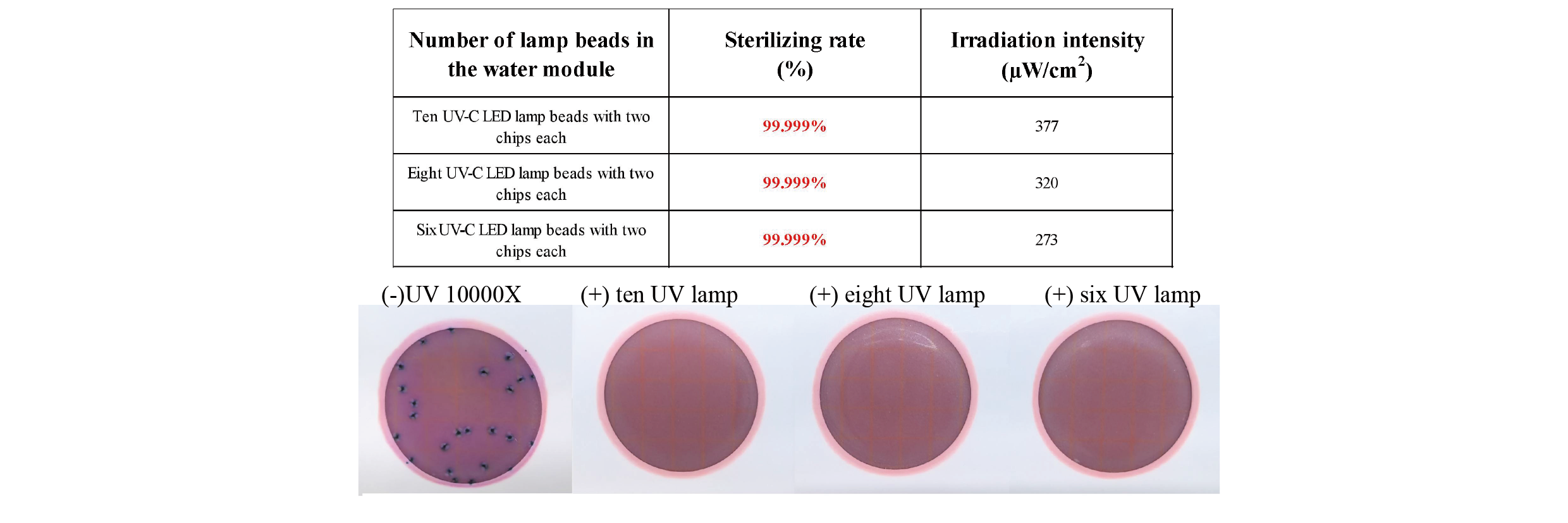

Abstract. This study systematically evaluated the sterilization performance and reliability of a UV-C LED water disinfection module based on 270–280 nm gallium nitride (GaN) high-power chips under various configurations, structural parameters, and pressure conditions. The experiment first analyzed the impact of the number of dual-chip UV-C LED beads on irradiation intensity and sterilization efficacy. At a flow rate of 9 L/min, configurations with 5-series-2-parallel (10 beads), 4-series-2-parallel (8 beads), and 3-series-2-parallel (6 beads) yielded irradiation intensities of 377 µW/cm², 320 µW/cm², and 273 µW/cm², respectively. The results demonstrated that, even with a 40%reduction in the number of beads and a 27.5% decrease in irradiation intensity, the system achieved a 99.999% inactivation rate for Escherichia coli.To further optimize system performance and cost, several structural improvements were implemented: replacing the aluminum substrate with a copper substrate reduced the optical power attenuation rate from 54% to 42%; increasing the quartz tube diameter from 6 mm to 16 mm effectively extended the water-UV contact time; and optimizing the aperture design of high-reflectivity materials improved light utilization efficiency. Based on these structural enhancements, tests were conducted using single-chip UV-C LED bead configurations (10, 8, and 6 beads), resulting in irradiation intensities of 305 µW/cm², 250 µW/cm², and 210 µW/cm², respectively, which were 19%–23% lower than those of equivalent dual-chip configurations. Nevertheless, the sterilization rate remained stable at 99.999%.Sealing and pressure resistance tests revealed that the module, sealed with food-grade silicone, achieved the designed flow rate of 9 L/min at an inlet pressure of 0.12 MPa, with a maximum pressure tolerance of 0.45 MPa. No leakage was observed during long-term operation, indicating excellent mechanical sealing and operational stability. This study provides critical experimental evidence and design references for developing efficient, cost-effective, and reliable UV-C LED water disinfection systems, facilitating their application in practical water treatment scenarios.

Keywords: Water Disinfection, UV-C LED, Escherichia coli, Sterilization Rate, Mercury-Free

1 Introduction

Drinking water safety is a critical criterion for assessing human health in daily life. However, drinking water used in everyday settings may become contaminated with pathogenic bacteria, protozoa, and viruses that cause waterborne diseases in humans and animals due to factors such as insufficient disinfection time, limited disinfection methods, or prolonged storage [1-4]. Secondary sterilization of domestic water before use can effectively reduce the transmission of waterborne diseases. Currently, common disinfection methods for inactivating viruses in water include traditional chemical chlorination, as well as physical disinfection techniques such as membrane filtration, ozonation, and ultraviolet (UV) irradiation [5-7]. Among these, ozone is the most effective disinfectant for inactivating bacteria, viruses, and protozoa, while chloramines exhibit the lowest efficacy but are more suitable for secondary water disinfection due to their slower reaction rates compared to chlorine and longer persistence in distribution systems. Additionally, chloramines produce lower levels of disinfection byproducts (DBPs) than chlorine, although microbial activity in distribution systems may generate nitrate ions when chloramines are used as residual disinfectants [6].

UV-C, as a chemical-free physical disinfection technology that does not produce disinfection byproducts, has garnered significant attention in microbial inactivation [8]. Although widely applied in air, water, and surface disinfection [9, 10], its limitations include low efficiency, frequent lamp replacement, and the environmental pollution caused by mercury-containing materials, which increase economic costs for users [11]. UV-C light-emitting diode (LED) technology based on gallium nitride (GaN) materials has emerged as a solution to address these shortcomings [12]. In addition to overcoming the drawbacks of mercury-based lamps, UV-C LEDs offer advantages such as long lifespan, high stability, compact size, and short warm-up time [13, 14]. These characteristics make UV-C LEDs an ideal choice for next-generation water disinfection technologies.

2 Material and Method

2.1 UV-C LED Beads

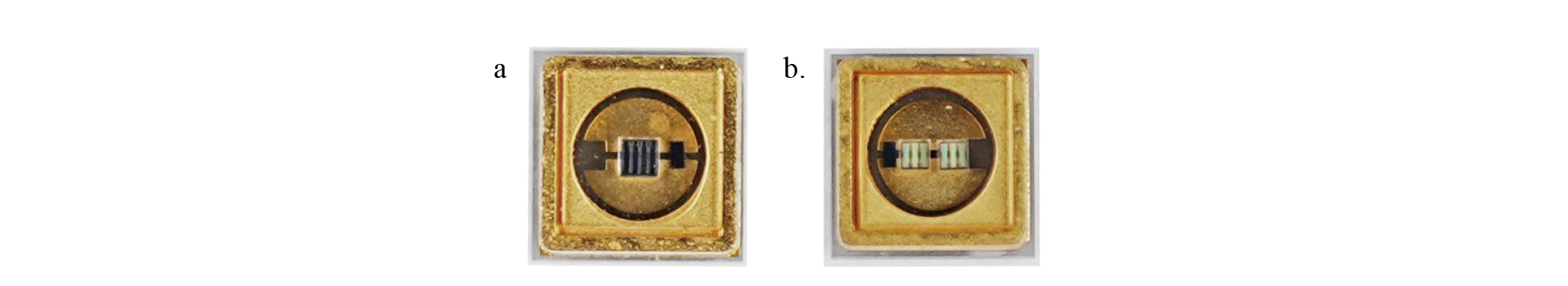

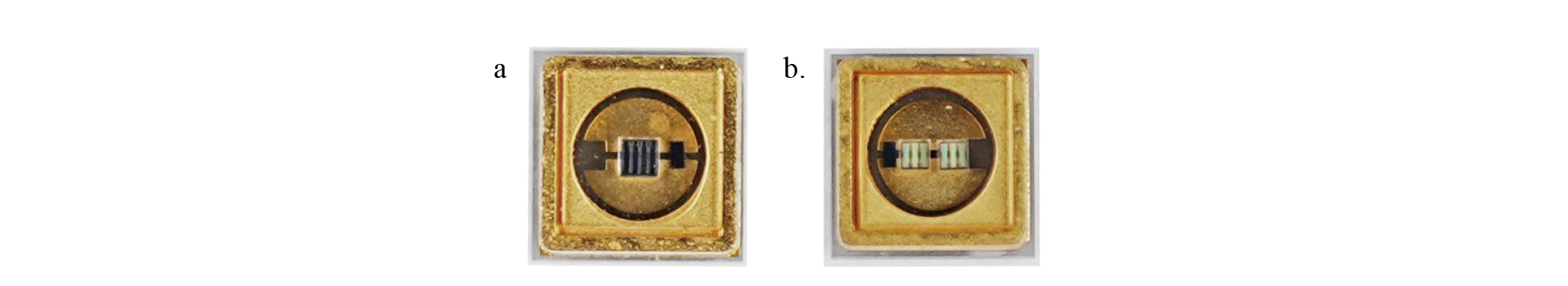

This study utilized high-power 270–280 nm gallium nitride (GaN)-based UV-C LED chips independently developed and produced by MASSPHOTON. Through an optimized eutectic bonding process, high-quality bonding between the chip and the ceramic substrate was achieved, reducing the interfacial void fraction and enhancing heat dissipation efficiency. Figure 1a illustrates a single-chip packaged LED bead with an irradiation intensity of up to 30 mW. When two chips were packaged, the irradiation intensity of the UV-C LED bead reached 50 mW, representing an overall efficiency improvement of 66.6%. This optimized packaging approach provides reliable technical support for the application of deep-ultraviolet LEDs in sterilization and disinfection fields.

Fig.1. MASSPHOTON LED Beads: a. Single-chip LED bead; b. Dual-chip LED bead

2.2 Test Strain

The second generation of Escherichia coli (8099) was streaked onto a culture plate for activation and set aside for use. Fresh E. coli slant cultures from the third to seventh generations, incubated at 36 ± 1°C for 18–24 hours, were inoculated into LB liquid medium and cultured in a constant-temperature incubator at 36 ± 0.5°C for 16–20 hours. After significant bacterial colony expansion, the cultures were stored at room temperature for subsequent use.

2.3 Detection Method

The detection method and calculation of log inactivation rate were performed in accordance with Appendix E of GB28235-2020, Hygienic Requirements for Ultraviolet Appliance of Disinfection, which outlines the laboratory method for microbial inactivation testing in water disinfection.

3 Results and Discussions

3.1 Introduction to Water Module Structure

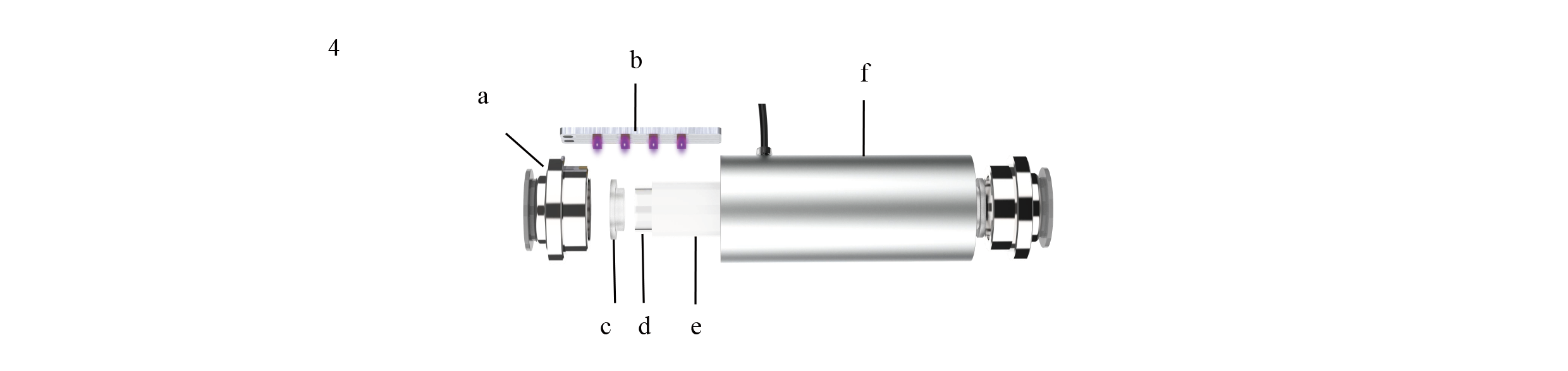

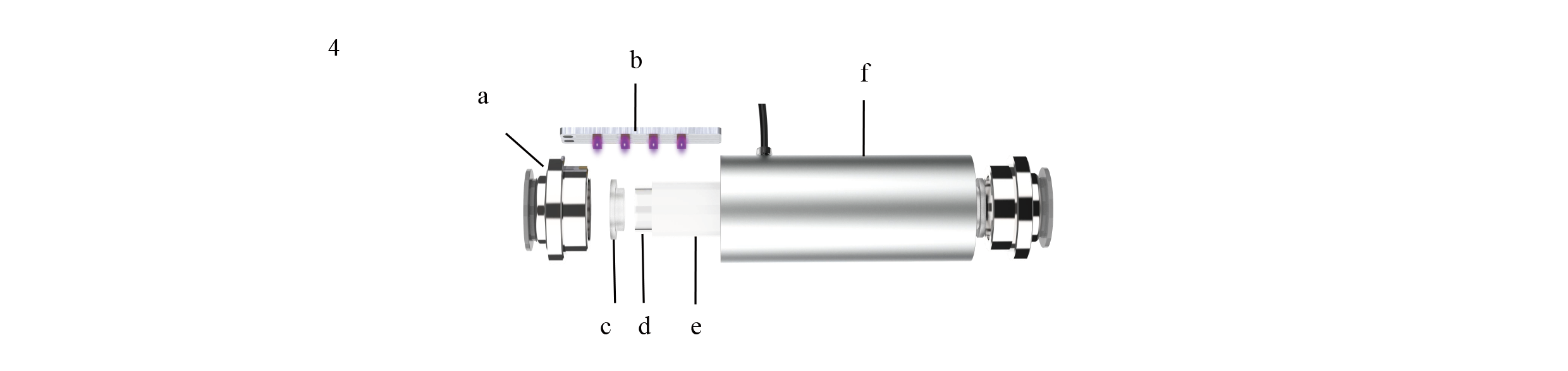

Aluminum rapidly forms a dense and robust aluminum oxide (Al₂O₃) protective film in air, which is compact and exhibits high chemical stability, preventing further oxidation of the underlying aluminum. Consequently, pure aluminum is highly resistant to rusting in dry air. Even in humid environments, as long as the oxide film remains intact (e.g., not compromised by strong acids or alkalis), its corrosion resistance significantly surpasses that of steel. Additionally, aluminum has a density of approximately 2.7 g/cm³, about one-third that of iron or copper, effectively reducing weight, making it an ideal material for the casing of the MASSPHOTON 9 L/min water disinfection module (Figure 2). To enhance the oxidation and corrosion resistance of the aluminum-based casing, researchers applied anodization treatment to form a thicker and denser oxide film on the aluminum surface, thereby improving its durability.

Fig.2. Product Diagram of MASSPHOTON 9 L/min Water Disinfection Module:a. Metal head b. UV-C LED board c. Waterproof silicone ring d. Quartz tube e. High-transmittance reflective material f. Metal sleeve

3.2 Study on Sterilization Efficacy of UV-C LED under Different Bead Configurations

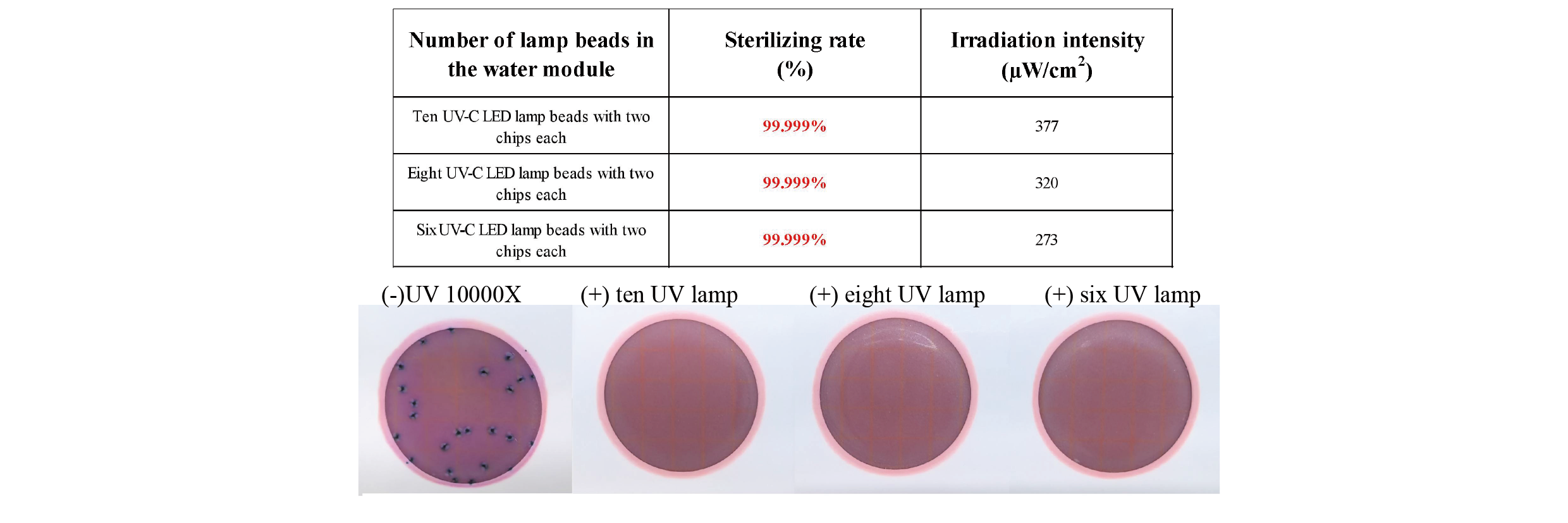

To investigate the relationship between the number of LED beads and the sterilization rate of flowing water, three configurations of dual-chip UV-C LED beads were tested: 5-series-2-parallel (10 beads), 4-series-2-parallel (8 beads), and 3-series-2-parallel (6 beads). The sterilization efficacy against Escherichia coli (ATCC 8099) was evaluated under identical water module specifications, with each bead supplied with a current of 200 mA.

Table 1.Relationship between the Number of Dual-Chip UV-C LED Beads, Sterilization Performance, and Irradiation Intensity

Fig.3. Relationship between the Number of Dual-Chip UV-C LED Beads and Sterilization Test Results

The experimental results (Table 1) demonstrate that, at a flow rate of 9 L/min and with an unmodified water module structure, the irradiation intensities for configurations using 5-series-2-parallel (10 beads), 4-series-2-parallel (8 beads), and 3-series-2-parallel (6 beads) dual-chip UV-C LED beads were 377 µW/cm², 320 µW/cm², and 273 µW/cm², respectively. Despite reducing the number of beads from 10 to 6, a 40% decrease, and the irradiation intensity from 377 µW/cm² to 273 µW/cm², a 27.5% reduction, the sterilization rate still achieved 99.999% (Figure 3), fully meeting the stringent standards for drinking water disinfection.

3.3 Study on the Impact of Quartz Tube Diameter and Chip Quantity on Sterilization Efficiency

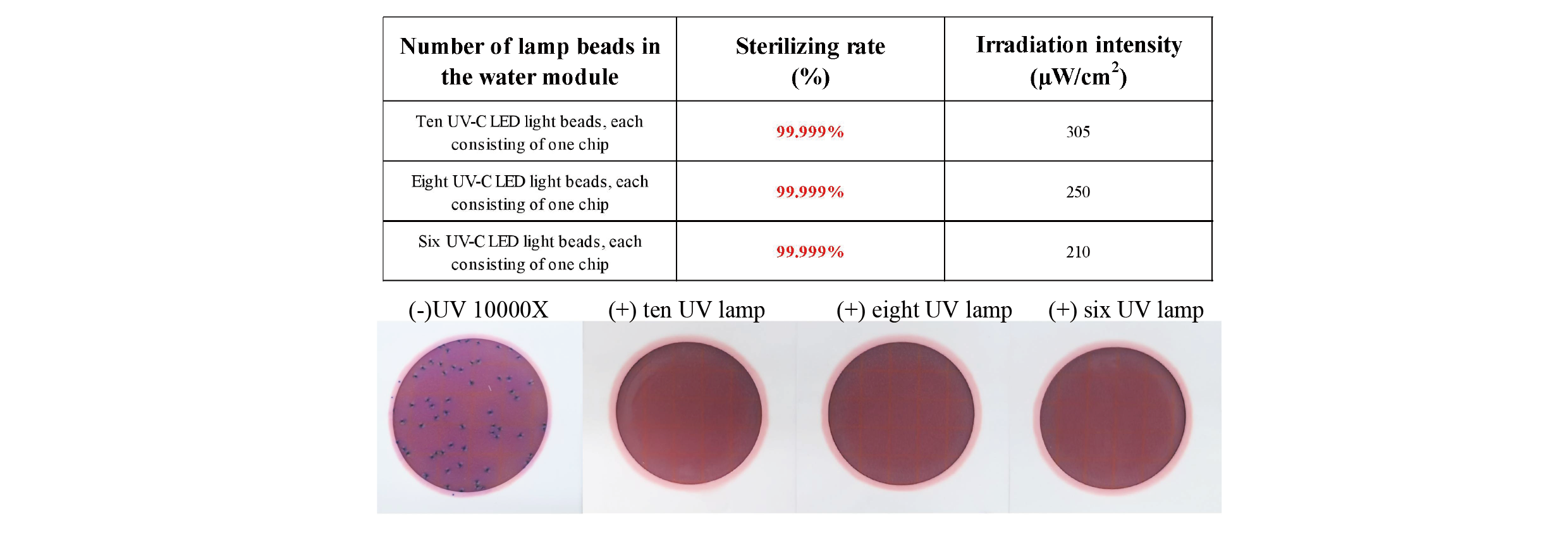

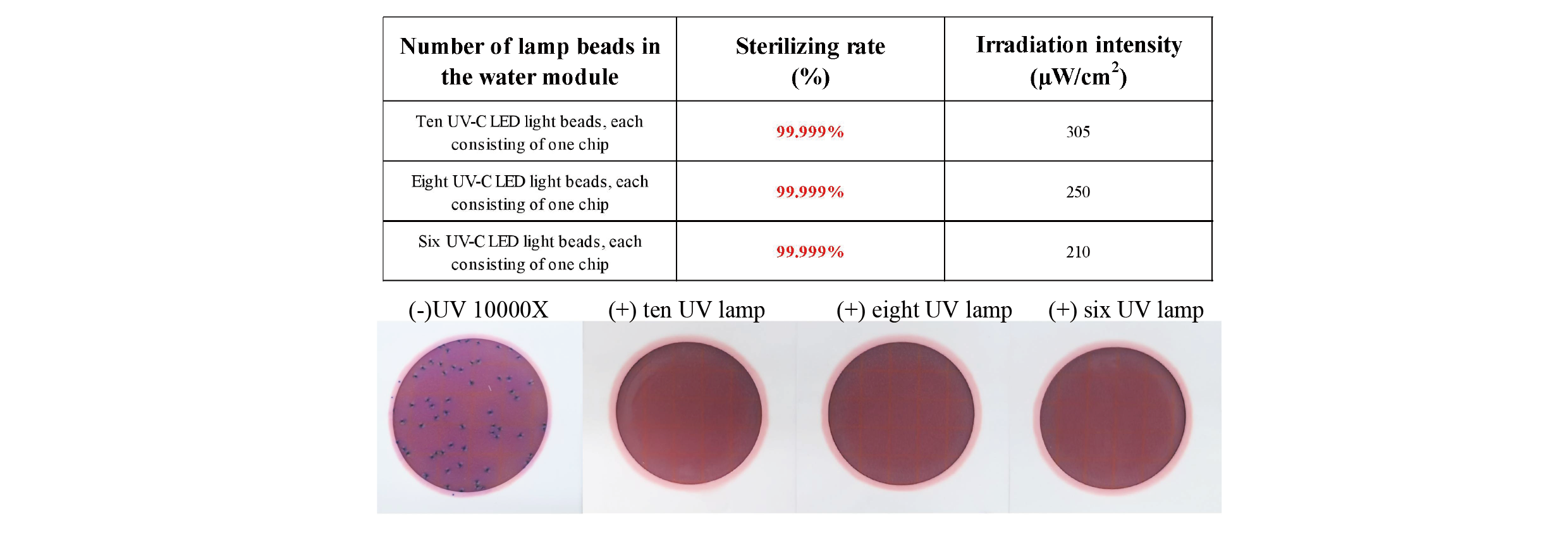

To achieve cost reduction while maintaining sterilization efficiency, the research team, based on prior test results showing that copper substrates significantly reduce the optical power attenuation rate of UV-C LEDs compared to aluminum substrates (42% vs. 54%), replaced the original aluminum substrate in the water module with a copper substrate. To extend the residence time of flowing water within the module, the quartz tube diameter was increased from 6 mm to 16 mm, allowing for prolonged water-UV contact time while maintaining the same flow rate. Additionally, the aperture design of the high-transmittance reflective material at the LED bead positions was modified from elongated slots to individual openings aligned with each bead, thereby enhancing disinfection efficiency. Building on these structural optimizations, subsequent experiments were conducted using single-chip UV-C LED bead configurations of 5-series-2-parallel (10 beads), 4-series-2-parallel (8 beads), and 3-series-2-parallel (6 beads).

Table 2. Relationship between the Number of Single-Chip UV-C LED Beads, Sterilization Performance, and Irradiation Intensity

Fig.4. Relationship between the Number of Single-Chip UV-C LED Beads and Sterilization Test Results

The experimental results (Table 2) indicate that, with configurations of 5-series-2-parallel (10 beads), 4-series-2-parallel (8 beads), and 3-series-2-parallel (6 beads) single-chip UV-C LED beads, the corresponding irradiation intensities were 305 µW/cm², 250 µW/cm², and 210 µW/cm², respectively. Compared to dual-chip UV-C LED configurations with the same number of beads, although the total number of beads remained unchanged, the irradiation intensity decreased by 19%, 22%, and 23%, respectively, due to the halving of chips per bead. With further optimizations, including an increased quartz tube diameter, replacement with a copper substrate, and the use of additional high-transmittance reflective materials, configurations with 10, 8, and 6 single-chip UV-C LEDs still achieved a sterilization rate of 99.999% (Figure 4), despite a 40% reduction in bead count and a 27.5% decrease in irradiation intensity, fully meeting the stringent requirements for drinking water disinfection.

3.4 Water Flow Rate Variations under Different Pressures

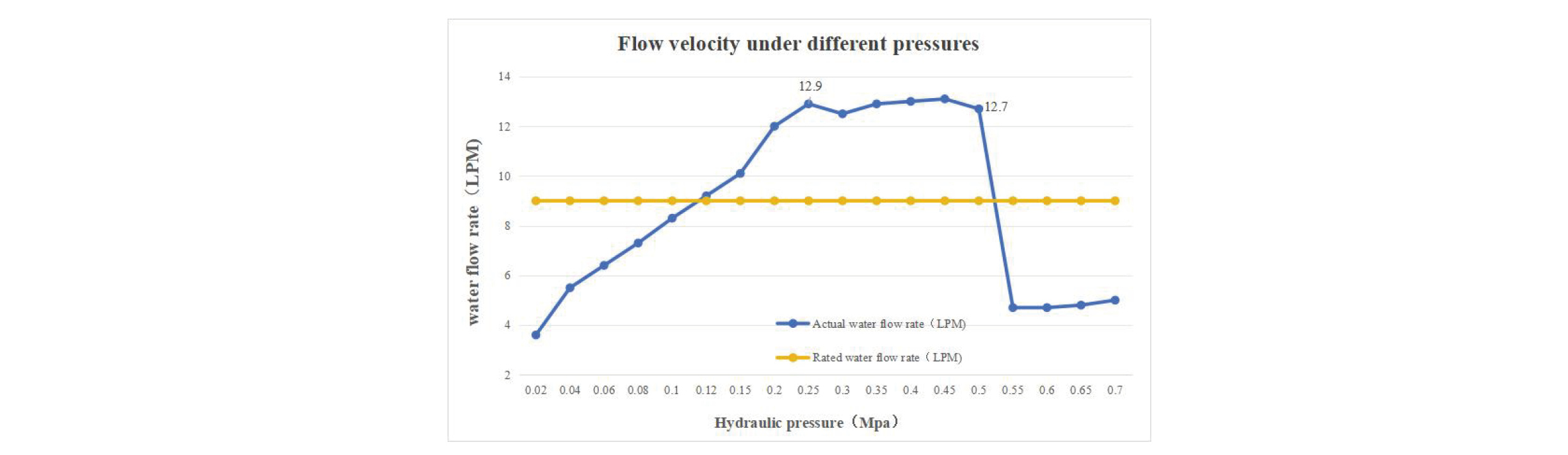

As a core component in direct contact with water, the watertight sealing and pressure resistance stability of the MASSPHOTON 9 L/min water disinfection module are critical prerequisites for ensuring safe operation. To meet these essential requirements, food-grade silicone seals were used for the inlet and outlet sealing components. This material not only exhibits excellent elasticity and aging resistance, allowing a tight fit with the interface structure to prevent water leakage, but also avoids secondary contamination of water quality due to material leaching during disinfection, balancing both sealing performance and safety. To further validate the reliability of the sealing design, researchers simulated real-world operating conditions, continuously monitoring changes in water flow rate through the module under varying pressure conditions to determine the module’s pressure tolerance range.

Fig.5. Water Flow Rate through the Water Module under Different Pressures

As shown in Figure 5, the current structure of the MASSPHOTON 9 L/min water disinfection module achieves a flow rate of 9 L/min at 0.12 MPa and a maximum flow rate of 12.9 L/min at 0.2 MPa, with no leakage observed during long-term operation tests. When the pressure increases to 0.42 MPa, the flow rate begins to decline, potentially due to deformation of the sealing ring caused by excessive pressure. These results indicate that, with adequate sealing performance, the flow rate remains stable without abnormal attenuation. However, if sealing defects (e.g., interface leakage) are present, the flow rate exhibits significant fluctuations due to pressure loss. The MASSPHOTON 9 L/min water disinfection module successfully passed pressure tests ranging from 0.12 to 0.45 MPa, demonstrating its excellent mechanical sealing performance and pressure resistance stability, ensuring no issues such as water leakage or pressure loss during long-term use.

4 Conclusions

This study systematically evaluates the key performance parameters of a UV-C LED water disinfection module, including the number of packaged chips, LED configuration, irradiation intensity, and pressure resistance, providing critical insights for developing efficient, low-cost, and low-risk UV-C LED sterilization systems. Experimental results demonstrate that replacing the original aluminum substrate with a copper substrate and increasing the quartz tube diameter enables the optimization of the UV-C LED configuration from a 5-series-2-parallel (10 LEDs) dual-core setup to a 3-series-2-parallel (6 LEDs) single-core setup, reducing the total number of chips from 20 to 6, significantly lowering chip costs. Additionally, pressure retention tests on the MASSPHOTON 9L/min water disinfection module indicate a maximum pressure resistance of 12.9 MPa, with no leakage observed during long-term operation, demonstrating excellent sealing and reliability.

In conclusion, through optimizations in materials and structure, this study achieves significant improvements in cost control and reliability of the UV-C LED water disinfection module while maintaining disinfection performance. Future research may focus on the long-term operational stability of higher-power UV-C LEDs, as well as the impact of industrial high-flow water conditions and varying water qualities on disinfection efficiency, to enhance the adaptability and widespread adoption of this technology in practical applications.

References

1. Griffiths, J.K., Waterborne Diseases. International Encyclopedia of Public Health (Second Edition), 2017: p. Pages 388-401.

2. Lanrewaju AA, E.A.S.S., A review on disinfection methods for inactivation of waterborne viruses. Front Microbiol, 2022(13:991856. doi: 10.3389/fmicb.2022.991856. PMID: 36212890; PMCID: PMC9539188.).

3. Lanrewaju AA, E.A.S.S., Global public health implications of human exposure to viral contaminated water. Front Microbiol, 2022(13:981896. doi: 10.3389/fmicb.2022.981896. PMID: 36110296; PMCID: PMC9468673.).

4. Tamele IJ, V.V., Microcystin Incidence in the Drinking Water of Mozambique: Challenges for Public Health Protection. Toxins (Basel), 2020(12(6):368).

5. Collivignarelli M. C., A.A.B.I., Overview of the main disinfection processes for wastewater and drinking water treatment plants. Sustainability, 2018(10:86.).

6. Ngwenya N, N.E.P.J., Recent advances in drinking water disinfection: successes and challenges. Rev Environ Contam Toxicol, 2013(222:111-70).

7. Li H, F.M.Y.X., Qualitative and quantitative analysis of the effects of drinking water disinfection processes on eukaryotic microorganisms: A meta-analysis. Chemosphere, 2023(332:138839).

8. Oguma K., R.S., UV inactivation of viruses in water: its potential to mitigate current and future threats of viral infectious diseases. Jpn. J. Appl. Phys., 2021(60:110502. doi: 10.35848/1347- 065/ac2b4f).

9. Mohaghegh Montazeri M, H.S.T.F., Ultraviolet light-emitting diode (UV-LED) water disinfection photoreactors: A review. J Environ Manage, 2025(386:125678. doi: 10.1016/j.jenvman.2025.125678. Epub 2025 May 14. PMID: 40373433.).

10. Shafa Muhammad, F.M.A.E., Study of UV-C LED Technology on In-door Air Disinfection: An Effective Mercury-free and Ozone-free Method to Irradicate Airborne Microorganisms.. 2024, Association for Computing Machinery, New York, NY, USA.

11. Čizmić M, L.D.R.M., Photocatalytic Degradation of Azithromycin by Nanostructured TiO₂ Film: Kinetics, Degradation Products, and Toxicity. Materials (Basel), 2019(12(6):873).

12. Würtele MA, K.T.L.M., Application of GaN-based ultraviolet-C light emitting diodes--UV LEDs--for water disinfection. Water Res, 2011((45(3):1481-9. doi: 10.1016/j.watres.2010.11.015. Epub 2010 Nov 16. PMID: 21115187.).).

13. Pelayo D, H.A.S.G., Performance of high-efficiency UV-C LEDs in water disinfection: Experimental, life cycle assessment, and economic analysis of different operational scenarios. J Environ Manage, 2024(364:121442.).

14. Pelayo D, R.M.S.G., Techno-economic evaluation of UV light technologies in water remediation. Sci Total Environ, 2023(868:161376).