Jichen Shen1, Tianqi Wu1, Jun Zou1,*, Peng Wu2 and Yitao Liao2

1 School of Science, Shanghai Institute of Technology, China

2 Liyu Advanced Technology Co.Ltd, China

Abstract:

Deep UV LED package is a hotspot of growing concern for research scholars, it is through the LED semiconductor light-emitting devices emit UVC band ultraviolet (typical wavelength 260 ~ 280nm), is a new type of healthy artificial light source, compared with the traditional UV light source mercury lamps, the deep UV LED has a wavelength of accurate and controllable, green, and so on many advantages. Due to the high-energy deep UV radiation capability, it has a strong bactericidal and inactivation effect on bacteria, viruses and other microorganisms. In recent years, with the continuous progress of deep packaging technology, the optical efficiency and reliability of deep UV LEDs have been significantly improved. This paper summarizes the key technologies of deep-ultraviolet packaging, the performance of deep-ultraviolet LEDs and the application of deep-ultraviolet LEDs; through the understanding of the packaging materials, packaging structure, packaging process and so on to improve the performance of deep-ultraviolet LEDs, so that it is better to apply to the market, which can be seen that the deep-ultraviolet LEDs have a great prospect for development.

Keywords: deep ultraviolet LED, encapsulation, property

*Corresponding author: Jun Zou, School of Science, Shanghai Institute of Technology, China. Email: zoujun@sit.edu.cn

1.Introduction

Deep ultraviolet (DUV) LED is a new healthy artificial light source, Deep UV LED and traditional UV light source compared to mercury lamps, there are many advantages such as precise wavelength control, green environmental protection and so on. [1], and it has received widespread attention in the fields of disinfection, chemical decomposition, water and air purification, and food safety control [2]. However, the challenge of DUV-LEDs in practical applications remains the low light efficiency.

In the past two decades, LEDs have been encapsulated in two-lead devices, similar in shape to small light bulbs, and sealed with highly transparent epoxy resins. However, there are several problems with this traditional encapsulation method. Because of the epoxy resin, it is susceptible to UV aging, which leads to the cracking of the encapsulated cross-section [3]. Therefore, quartz encapsulation is usually used to solve this problem, but due to the huge difference in refractive index, encapsulation with quartz glass will cause Fresnel reflection losses at the glass-air and chip-air interfaces, and these reflection losses will cause reflection glare and reduce the light transmittance, which will lead to a decrease in the optical output power of the glass encapsulated DUV-LEDs [4]. In response to this phenomenon, researchers have also proposed new solutions, such as the improvement of quartz glass material and encapsulation with amorphous fluorine resin.

Different substrate materials also have a great impact on the photothermal performance of deep-ultraviolet LEDs. Since the traditional DUV-LEDs package has sapphire with a high refractive index, total internal reflection occurs easily. Later DUV-LEDs are packaged using an aluminum nitride (AlN) ceramic substrate, the substrate in the ultraviolet band has a high absorbance photons are absorbed by the aluminum nitride ceramic substrate, which reduces the LEE of DUV-LEDs [5]. In response to this problem, some subsequent researchers have proposed Si-PKG, which improves its light extraction efficiency. On the other hand, different substrate materials have different heat dissipation capabilities, and the effect of thermal issues can prevent LEDs from realizing their true potential [6].

Whether different encapsulation methods can be used in practical applications, the encapsulation process cannot be ignored. In the encapsulation process, if the operation is not proper, it will be easy to produce voids, and the main factors affecting the formation of voids are the solder material and reflow process conditions, as well as the location and size of the solder joints. In response to this problem, researchers and scholars have also proposed many programs to solve it.

Despite the rapid development of LED technology in terms of luminous efficiency and cost, package reliability is still one of the main challenges for LED systems. The emergence of various new packaging methods provides new ways to improve LED performance and reliability.

2. Key Technologies of Deep UV Packaging

2.1. Selection of packaging materials

First of all, deep UV light-emitting diodes face problems of light extraction, optical performance limitation, and mechanical protection in the encapsulation process. Conventional encapsulation materials (silica gel or epoxy resin) are easy to be aged and destroyed due to DUV light-induced molecular dissociation. For organic e-encapsulate materials, some scholars have proved that the only organic material that can be used to encapsulate DUV-LEDs is considered to be polymerized perfluoro(4-ethenoxy-1-butene) (p-bVE) encapsulated with the CF3 end-groups of 1.35, which is the only organic material that can be used to encapsulate DUV-LEDs at present. CF3-terminated polymerized perfluoro(4-vinyloxy-1-butene) (p-BVE) [7].

When organic materials are not used, some researchers and scholars through experiments in 20mA, 25 ℃ after 500h aging test, the use of quartz hermetic encapsulation of the radiant power maintenance rate than the use of silica gel encapsulation is 13% higher than that of the silica gel encapsulation of the LED's intensity with the aging time and significant attenuation[8]. However, the light extraction efficiency using glass encapsulation is limited and the encapsulation process is complicated.

Therefore, to address this problem, some researchers have proposed amorphous fluorine resin as the encapsulation material for DUV-LEDs, which improves the light extraction efficiency due to its non-absorption properties in the DUV wavelength region and also avoids the problem of deep ultraviolet aging and damage. In this regard, some researchers and scholars have prepared DUV-LEDs encapsulation devices with different thicknesses of fluorocarbon resin coatings and different output powers by using the drop-coating method and tested their characteristics. The results show that the output power increases from 4.95 mW to 5.44 mW at 40 mA with the use of fluorocarbon resin film packaging, the cost can be reduced by about 10%, and the material is more suitable for low-power DUV-LEDs [9].

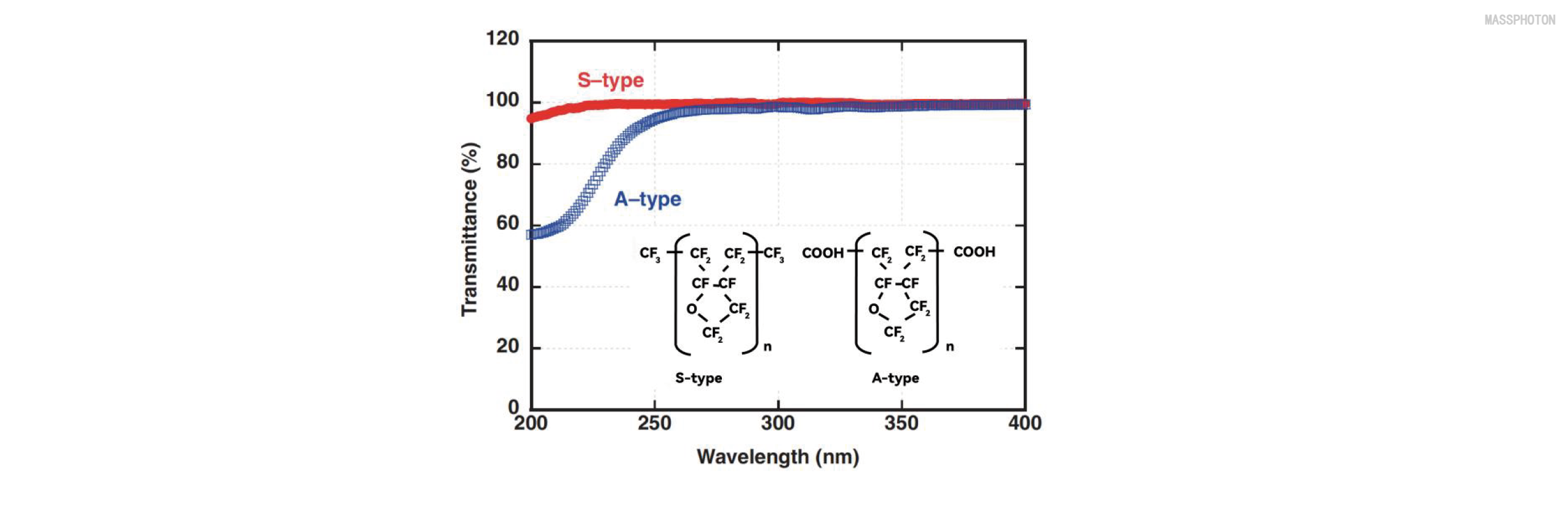

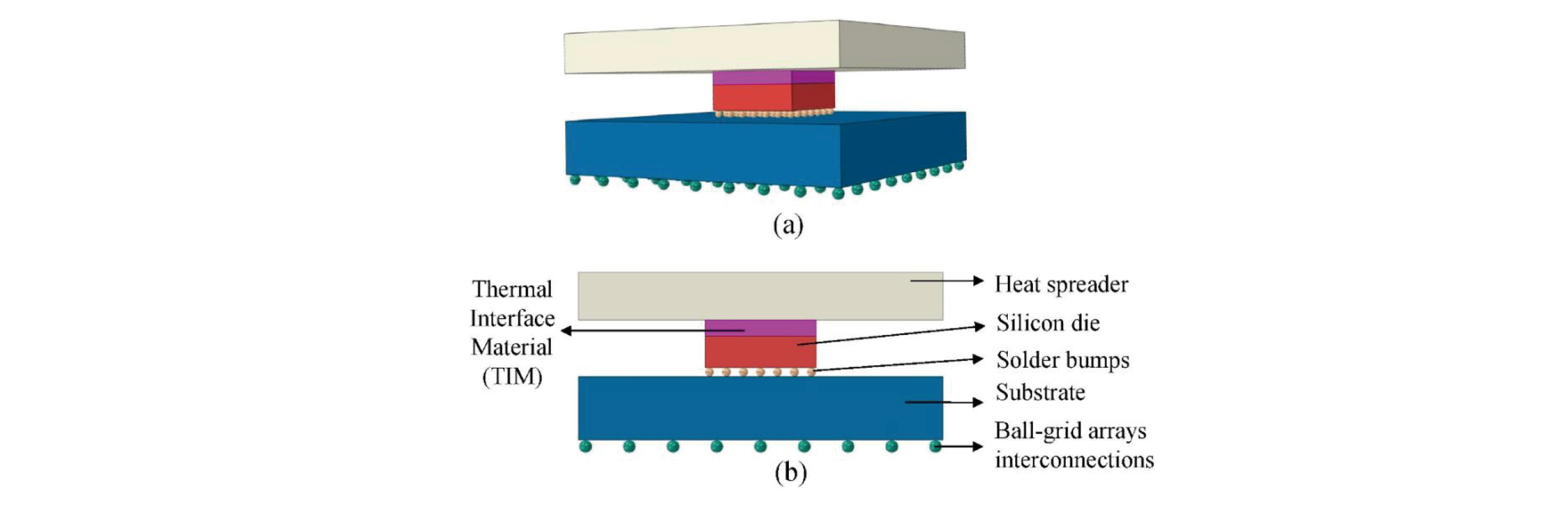

For fluororesin thin-film encapsulation, it has also been shown that fluororesins also have potential as bottom-filling and encapsulation materials, but existing resins are only suitable for wavelengths greater than 330 nm. To address this issue, researchers have explored bottom-filling and encapsulation methods using fluorosis, and they have proposed optically isotropic and stable amorphous fluororesis and attempted to use them for encapsulation. The amorphous fluorosis structure is shown in Figure 1. It was concluded that a suitable resin for DUV-LEDs encapsulation is a fluororesin terminally capped with trifluoromethyl. This amorphous S-type resin is considered to be sufficiently durable and effective as a bottom filler material to avoid short circuits, making it ideal for DUV-LEDs encapsulation [10].

Figure 1

Absorption spectra of amorphous fluorine resins between 200 and 400 nm. The resin structures are shown in the inset

Overall, encapsulation technology and material selection for deep-ultraviolet light-emitting diodes (DUVs) are critical for improving light output power and optical performance. Amorphous fluoro resin film encapsulation and fluoro resin-filled encapsulation are two promising encapsulation methods to improve light extraction and optical performance. However, further research and improvements are still needed to solve the problems faced by fluorosis, such as decay and high cost.

2.2. Optimization of packaging materials

Fluoropolymers are a candidate encapsulation material where amorphous fluoropolymers have high UV transparency and UV resistance. However, pure fluoropolymers reduce the light extraction efficiency of DUV-LEDs. To improve the light extraction efficiency, the researchers proposed a new approach based on fluoropolymer encapsulation layers doped with aluminum nitride. And results were obtained to show that the method can indeed achieve improved light extraction efficiency and long-term optical stability of DUV-LED COB modules. [11]. Another researcher proposed an aluminum nitride doped silica-filled chip side (ASFCS) encapsulation method, which was experimentally shown to reduce the side light loss and improve the radiation efficiency of deep ultraviolet light emitting diodes (DUV-LEDs) [12].

In addition, for the packaging of AlGaN-based deep-ultraviolet LEDs, the researchers also studied the main chain structure of optically isotropic amorphous fluorine resins. It was found that for resins with two oxygen atoms in the ring, the visible damage to the electrode and the significant increase in leakage current were thought to be caused by photolysis of the ring induced by deep UV light irradiation. In contrast, in the case of resins with a single oxygen ring, no electrode damage and increased leakage were observed. This suggests that the monooxygenated resins are more suitable for encapsulation of DUV-LEDs. [13].

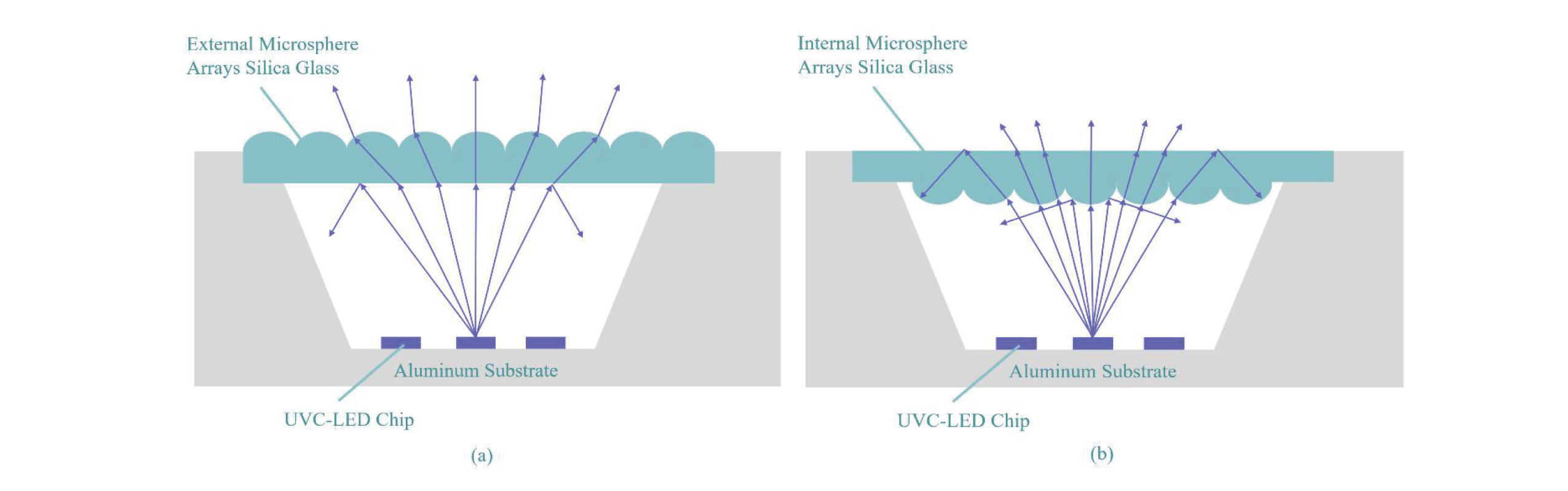

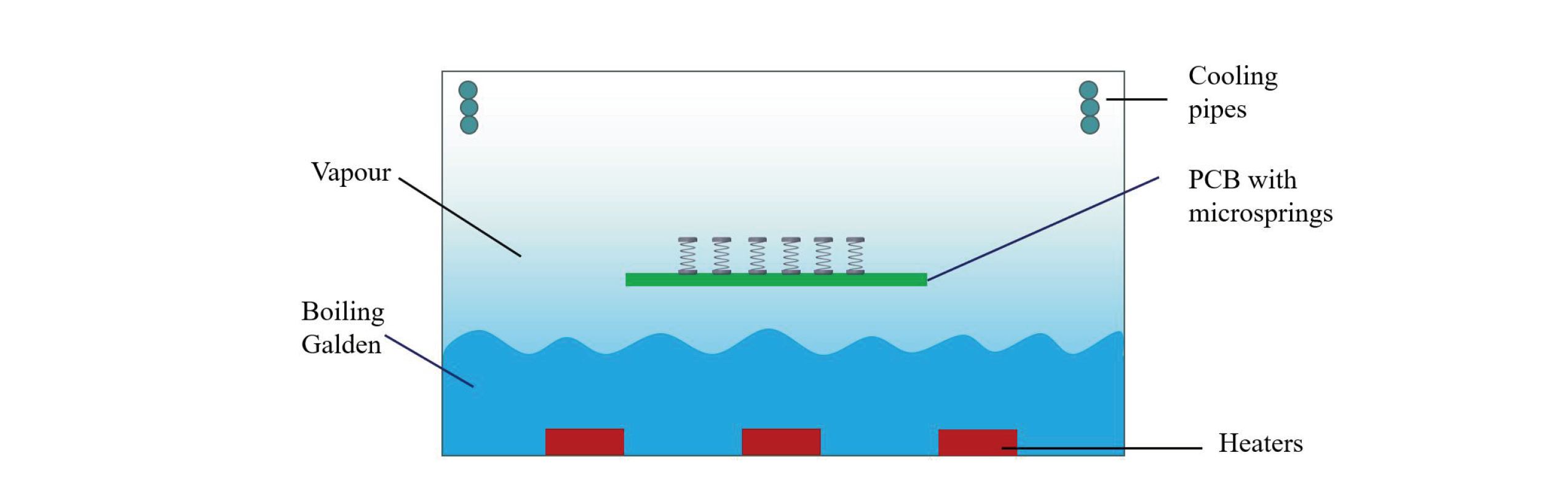

What's more, some research scholars proposed a micromachining method for quartz lenses, which can simultaneously design the inner and outer surfaces of the lenses for better control of the optical path and uniform illumination of light-emitting diodes (LEDs). They used the Monte Carlo method to track the UV light and performed numerical simulations to analyze the effect of different array microprocessing structures on the UV light using a rigorous coupled wave analysis method [14].

The results of the study show that the intensity of 265 nm UVC-LEDs can be significantly enhanced by using micromachined arrays. As the size of the internal quartz micromachining increases, the enhancement effect of the lens on the UV light increases. In addition, micromachining can enhance the concentration of light and effectively increase the intensity of UV light. Simulation and computational results show that the illumination uniformity can be greatly improved and the minimum Fresnel loss as low as 7.67% can be achieved by this free-form lens design [14].

It can be concluded that the researchers have achieved better light path control and uniform illumination effect through the micromachining method of free-form lenses. This is of great significance for the development of high-quality UV LED lighting and brings new possibilities for the lighting industry. However, this research is only numerical simulation and simulation results, and further experimental verification and engineering applications are needed. As shown in Figure 2.

Figure 2

(a) Silicon dioxide glass structure for external microprocessor arrays (b) Internal microprocessor arrays

In response to the improvement of quartz glass material, another researcher and scholar proposed solid-liquid hybrid gel (SLHG) to fabricate DUV-LED organic lens, which was found to greatly improve the efficiency of deep UV light extraction. A solid-liquid hybrid gel was structured using a solid crosslinked network of polydimethylsiloxanes to maintain the liquid component of the silicone oil, and exhibited excellent moldability, DUV transparency (over 90% transparency in the UVC range, and over 90% light transmission), and thermal stability. It was finally concluded that the use of SLLHG organic lenses would greatly improve the optical performance of DUV-LEDs. [15].

In summary, the light extraction efficiency, optical stability and efficacy of DUV-LEDs can be improved by employing different encapsulation materials and techniques, such as quartz glass covers, AlN-doped fluoropolymers, amorphous fluorine resins with specific structures, and changing the material of the quartz lens. However, further research and development is still needed to find more optimized packaging solutions.

2.3. Packaging substrates of different materials

Since a single chip cannot meet the conditions for actual sterilization and disinfection of deep UV LEDs, chip-on-board (COB) is a mature technology currently used by researchers to directly package multiple chips on a single substrate and can meet the disinfection and sterilization requirements of UVC LEDs [16]. Therefore, in practical applications, researchers need to select COB substrates for deep UV LED packaging from different packaging densities according to industrial applications. Some studies have shown that due to the presence of an insulating layer, the thermal conductivity of aluminum substrates is low, so they can accommodate a maximum package density of 0.38 W/mm2. However, alumina ceramic substrates can accommodate package densities of 0.94 W/mm2. Aluminum nitride ceramic substrates can accommodate higher package densities [17].

An aluminum nitride ceramic package (AlN-PKG) can effectively improve the thermal performance of deep-ultraviolet LED due to its good thermal stability and low thermal resistance, although it is widely used at present, AlN-PKG itself is expensive, and the use of polished-surface AlN ceramic base will also increase the total cost of the device [18]. Therefore, researchers have proposed AlGaN/AlN epitaxial layers grown on ordinary sapphire substrates to solve the problem of the high cost of ALN, which is also the focus of scientists' research.

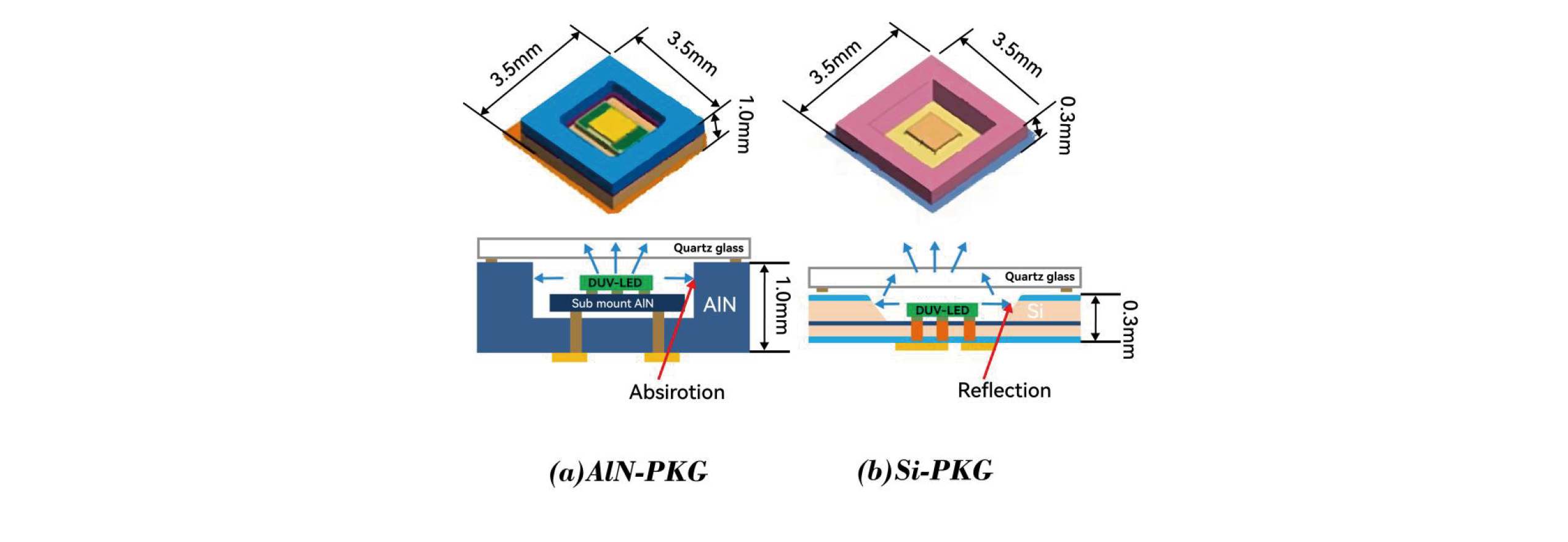

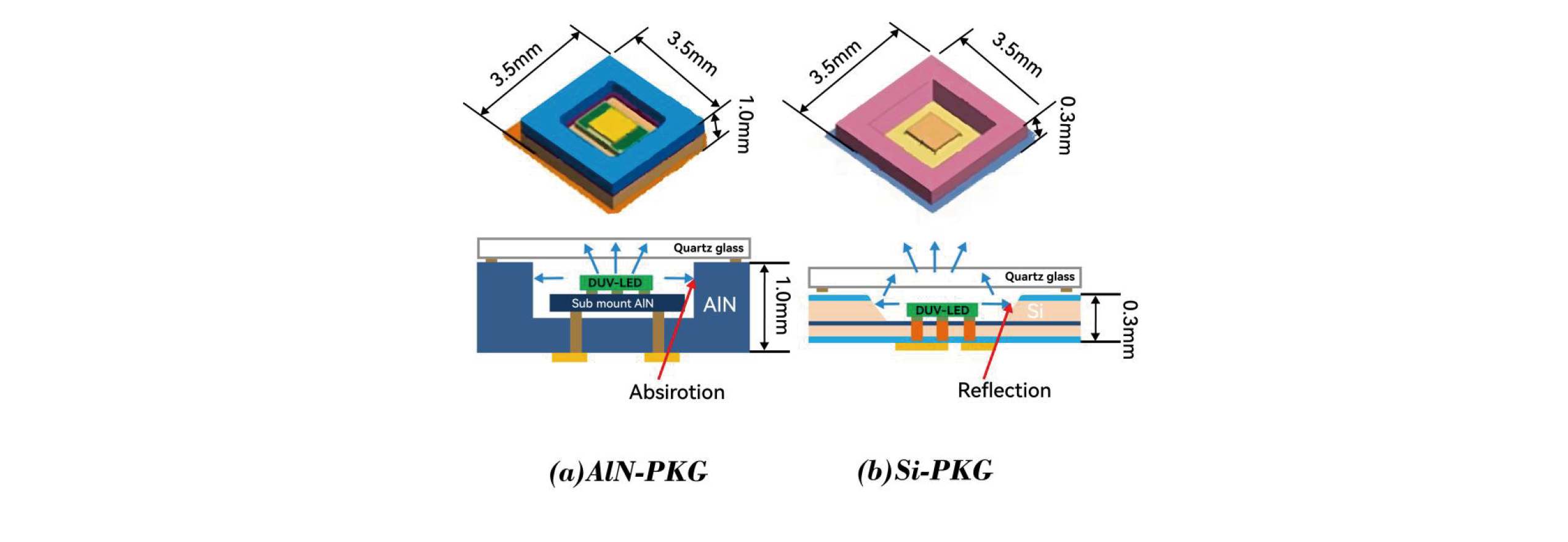

However, the choice of materials for the substrate is also being constantly revolutionized, and in recent years a new type of si package has also been studied, with a volumetric optical power density of 13.6 mW/mm3 [19]. As can be seen in Figure 3 for the AlN package and the Si package, the horizontal light at the bottom of the cavity can be reflected through the anisotropically etched cavity sidewalls of the Si-PKG, which increases the light output rate.

Figure 3

AlN-PKG vs. Si-PKG

With the use of a silicon base package, DUV-LEDs can achieve a smaller size, thanks to high-density integration, thin package layer, strength and rigidity, and good thermal performance. These advantages make the silicon base package more ideal choice, especially for the need for miniaturization and high performance of the deep ultraviolet light source applications, so the use of Si package can also reduce the cost of packaging.

However, some problems need to be solved using Si packages, such as the through-hole design and the chip soldering method that need to be modified when interconnecting DUV-LEDs chips with Si-PKGs[20]. By improving the current problems, it is hoped that the problem of interconnecting DUV-LED chips with Si-PKGs can be solved and that Si packages are expected to replace expensive ALN packages shortly [21].

Some researchers and scholars have even proposed 3D ceramic substrate packages, which are made by bonding quartz caps to three-dimensional (3D) ceramic substrates at low temperatures. The bonding layer is formed by an inorganic binder, which presents a reliable and dense state. Ceramic substrates are thermally stable and can effectively improve the stability of LED devices. However, the fabrication of 3D ceramic substrates is very energy-intensive, and copper plating is inefficient ,and costly [22].

Although choosing the right substrate material will improve the performance of deep-ultraviolet LED, improving the efficiency and reliability of LED packages is still an ongoing challenge [23]. With the continuous development of technology and research, it is believed that more innovative solutions will emerge to bring better performance for LED packaging.

3. Deep UV LED Performance

3.1. Package structure design improves deep UV thermal performance

Despite the significant progress and commercialization of deep UV LEDs, many challenges remain [24]. For example, the light extraction efficiency (LEE) of DUV LEDs is quite low and the efficiency is still much lower than that of blue LEDs [25]. Light extraction efficiency is a key challenge in the development of high-power DUV-LEDs, while thermal performance also needs to be enhanced [26]. This has been a catalyst for ongoing research.

To enhance the heat dissipation characteristics of LED packages, several researchers have taken various approaches. One of the studies introduced ceramic barrier ribs between the LED chips, which were measured by a FLIR T-250 infrared camera and were found to reduce the top surface temperature of the package and the junction temperature, thus improving the heat dissipation [27]. Another study explored the use of liquid encapsulation structures to improve light extraction efficiency and reduce thermal resistance. The study used silicone oil as the encapsulation material and conducted experiments on planar and lensed 281 nm deep-ultraviolet LEDs, and the results showed that liquid encapsulation can significantly increase the optical power and applies to deep-ultraviolet LEDs with different wavelengths.In addition, the liquid encapsulation structure can reduce the thermal resistance and further improve the performance of the LEDs [28]. However, due to the immaturity of the current technology, liquid encapsulation may have a certain impact on the reliability of device sealing. For high-power light sources, their lifetime may also be affected to some extent.

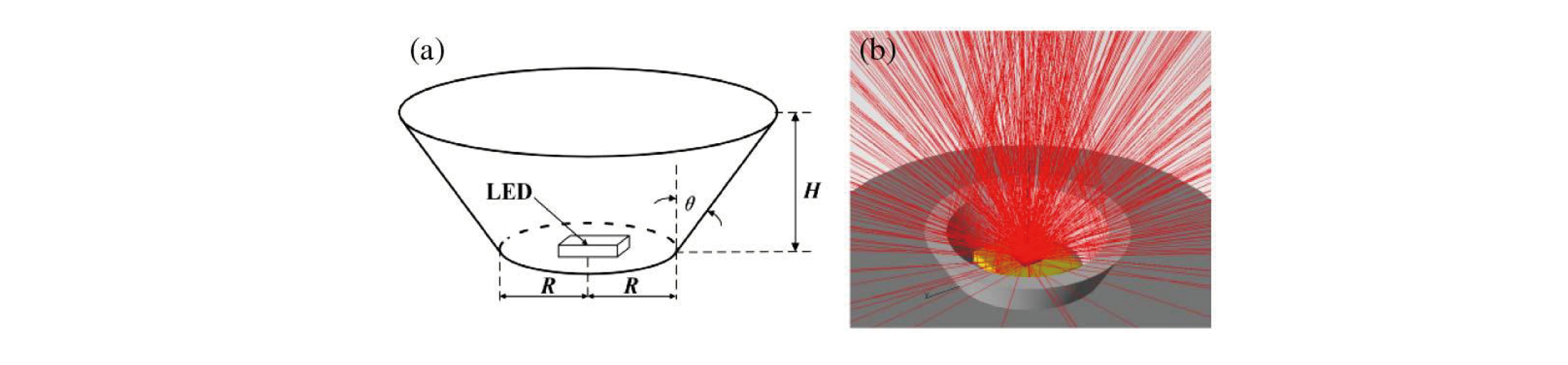

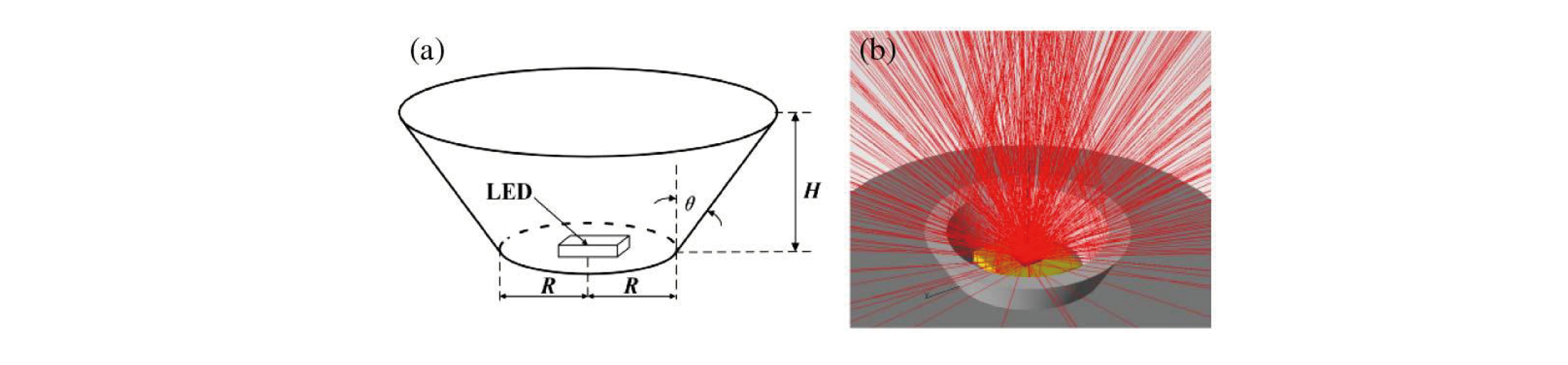

In addition to improving thermal performance, many efforts have been made to enhance LEE over the past decades, among which nanostructure patterning is one of the most widely studied and applied techniques [29]. A specific study has proposed to enhance the light extraction efficiency of DUV LEDs by utilizing a double-layer nanopatterned array (NPA) packaging method. This method modulates the interfacial light field to significantly enhance the light extraction of LEDs by combining high-quality polymer materials and nanoarray structures. The physical mechanism was verified by theoretical finite element analysis simulations, and the method was demonstrated to have the advantages of low cost, direct process, and effective enhancement of light extraction efficiency [30]. Some researchers and scholars have also found that Aluminum (Aluminum) is a material with good reflective properties to improve the light extraction efficiency of deep UV LED, and the reflectivity in the whole UV spectral range is about 0.92. By optimizing the characteristic dimensions of the reflector such as the angle, the height, and the inner radius, the light extraction effect of the sidewall emission of the DUV-LEDs can be enhanced. The researchers established an optical model of the DUV-LEDs and fabricated optimized reflectors with different reflectivities, which were then applied to the packaging of the DUV-LEDs. As shown in Figure 4 [31]

Figure 4

(a) Geometric and (b) optical model of DUV-LED packaged by Al reflector

Later, some research scholars also used two types of high-voltage flip-chip deep-ultraviolet light-emitting diodes (HV-FC DUV-LEDs) consisting of 2×2 and 3×3 cells, respectively, where each cell is made of tilted sidewalls covered by SiO2/Al. Simulation results show that the structure of inclined sidewalls is more favorable for the extraction of transverse magnetically polarized light. As a result, the HV-FC DUV-LEDs composed of 3 × 3 cells can realize higher optical power [32]. For this conclusion, another researcher and scholar proposed an innovation and found that the light extraction efficiency of AlGaN-based DUV LEDs could be improved by integrating a remote reflector and an air cavity into the tilted sidewall, and the remote reflection was realized by using an air cavity extractor based on a remote metal reflector. The remote reflection avoids light absorption and also supports additional light escape channels to enhance the LEE compared to the conventional deep UV LEDs formed by tilted sidewalls with metallic aluminum reflectors [33].

As for the problem of low light extraction efficiency of the traditional quartz glass cover, some research scholars have established the optical model of the deep-ultraviolet LEDs and investigated the optical performance of the deep-ultraviolet LEDs by optical simulation, and concluded that the DUV-LEDs with 3D quartz lenses exhibit higher light efficiency than the DUV LEDs with traditional quartz lens structures. This was attributed to the significantly enhanced light extraction emitted from the sidewalls of the DUV-LEDs chip [34]. Another researcher proposed to improve the LEE of DUV-LEDs by nanolithography and nano lens arrays (NLAs) fabricated by a wet etching technique and verified its theoretical feasibility by Monte Carlo ray tracing method and finite element analysis, which showed that both light and electric field distributions were improved by using the nano lens array (NLA) structure [35].

In summary, through the above technical research and innovation, it is expected to improve the photothermal management problem of deep UV LEDs and enhance the luminous efficiency and reliability of UVC LEDs. Despite the difficulties, these advances provide more possibilities and development space for future UVC LED applications.

3.2. Formation and effects of voids

Solder voids are a major reliability issue in chip-scale packaged electronic devices. The main factors affecting the formation of voids are the solder material and reflow process conditions, as well as the location and size of the solder joints; according to the size of the voids, they can be classified into macro-voids and micro-voids, whose formation is mainly affected by the soldering profiles, the amount of solder paste, the composition of the fluxes and their dosage; Macro-voids are formed by evaporation of the flux portion of the soldering process. When they are not allowed to leave the joint area during the liquid phase of the alloy, they are trapped in the joint forming voids [36]. Voids can affect the quality of the welded joint and, the mechanical and electrical properties of the joint. A large void area can also negatively affect the thermal conductivity of the joint, which usually leads to heat loss and cooling problems for overheated components, thus voids can have a huge impact on the thermal performance of deep UV LEDs [36].

It has been shown that the morphology of voids has an impact on the thermal resistance of chip-scale packaged electronics. By introducing three-dimensional finite element analysis, the researchers evaluated the effect of cylindrical and spherical voids. The results show that the thermal resistance of aggregated voids increases more for the same percentage of voids. Meanwhile, voids through the entire thickness of the solder layer and close to the heat-generating region of the chip significantly increase the package thermal resistance and chip junction temperature [37].

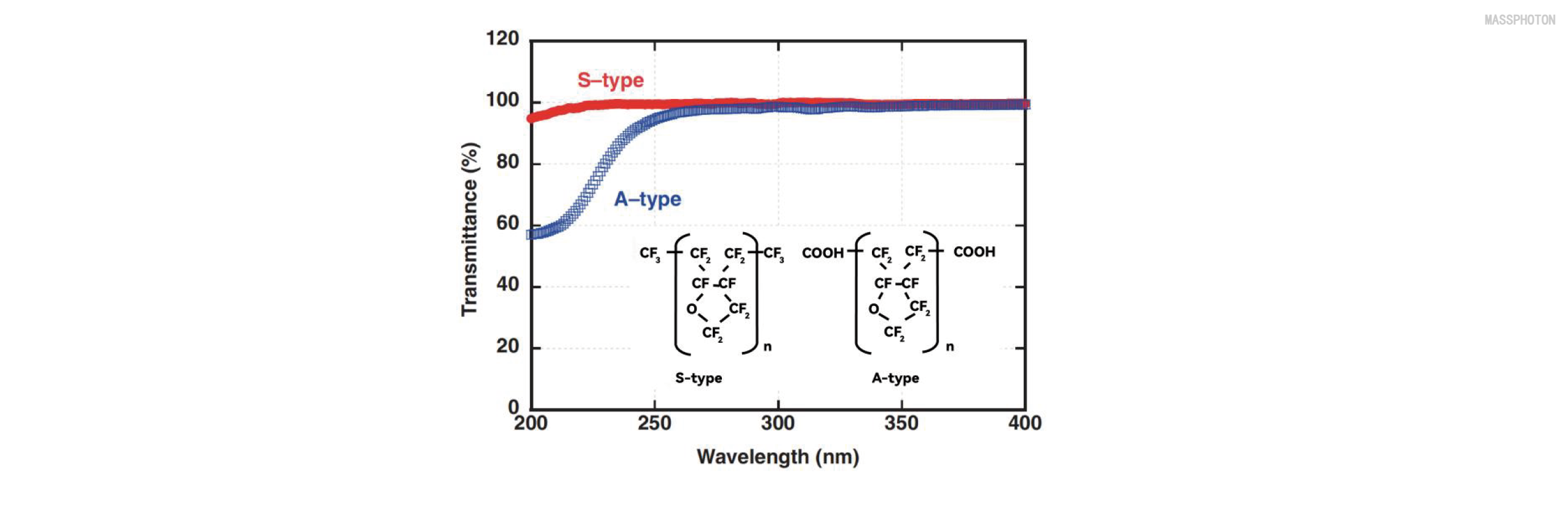

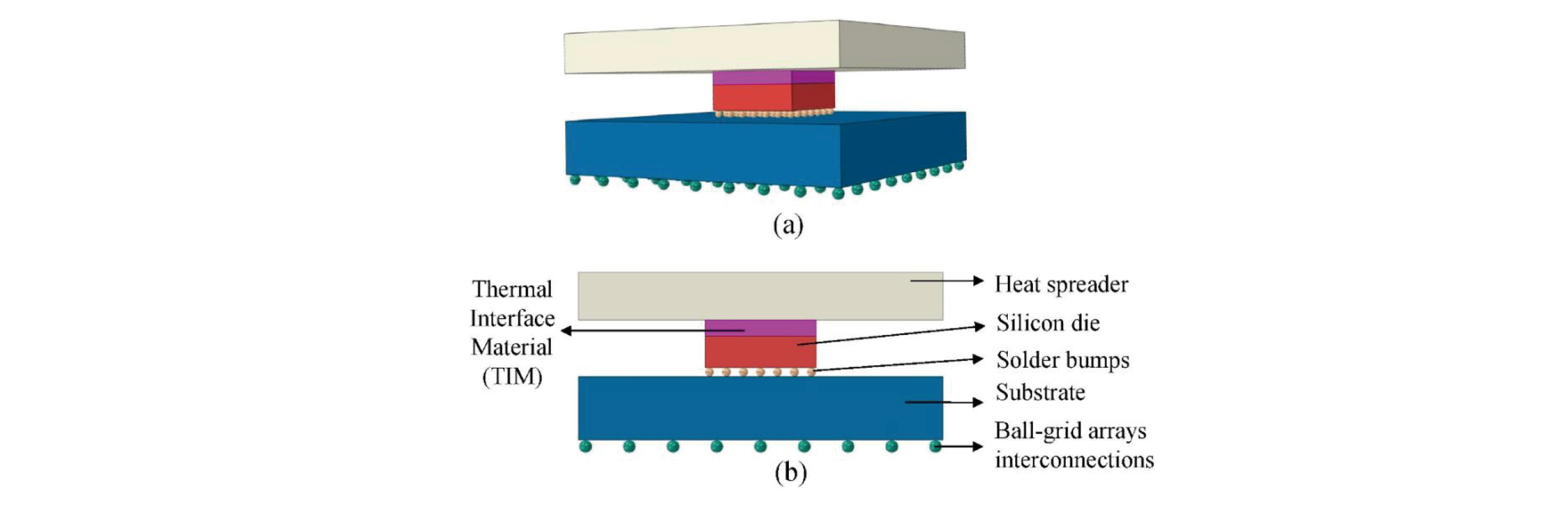

Some researchers and scholars have also proposed to enhance the heat transfer between the chip and the heat sink by introducing a thin layer of thermal interface material (TIM), i.e., a chip bonding layer. TIM suppresses interstitial air gaps and ensures that the heat can be transferred efficiently. TIM can be either polymer-based or solder-based, and the solder thermal interface material has been favored over the polymer-based material because it has higher thermal conductivity. However, when using solder as a thermal interface material, voids can easily form during the manufacturing/reflow process, especially in lead-free solder. The presence of voids reduces the effective solder cross-sectional area, leading to increased thermal resistance and higher peak chip temperatures, potentially triggering temperature-activated failure mechanisms. Voiding remains a major reliability issue [38].

To address this issue, the researchers also used 3D finite element analysis to investigate different voids. Meanwhile, voids that run through the entire thickness of the solder layer and are located close to the heat generation region of the chip significantly increase the package thermal resistance and chip junction temperature. As shown in Figure 5 [39].

Figure 5

A schematic representation of a typical flip-chip CSP arrangement showing (a) isometric and (b) planar views, with the different components identified on the planar view

In summary, solder voids have an important impact on package thermal resistance and chip junction temperature. By introducing a thin layer of thermal interface material (TIM) and further investigating the void morphology, the thermal conductivity of chip-scale packaged electronics can be improved and reliability can be improved.

3.3. Resolving voids

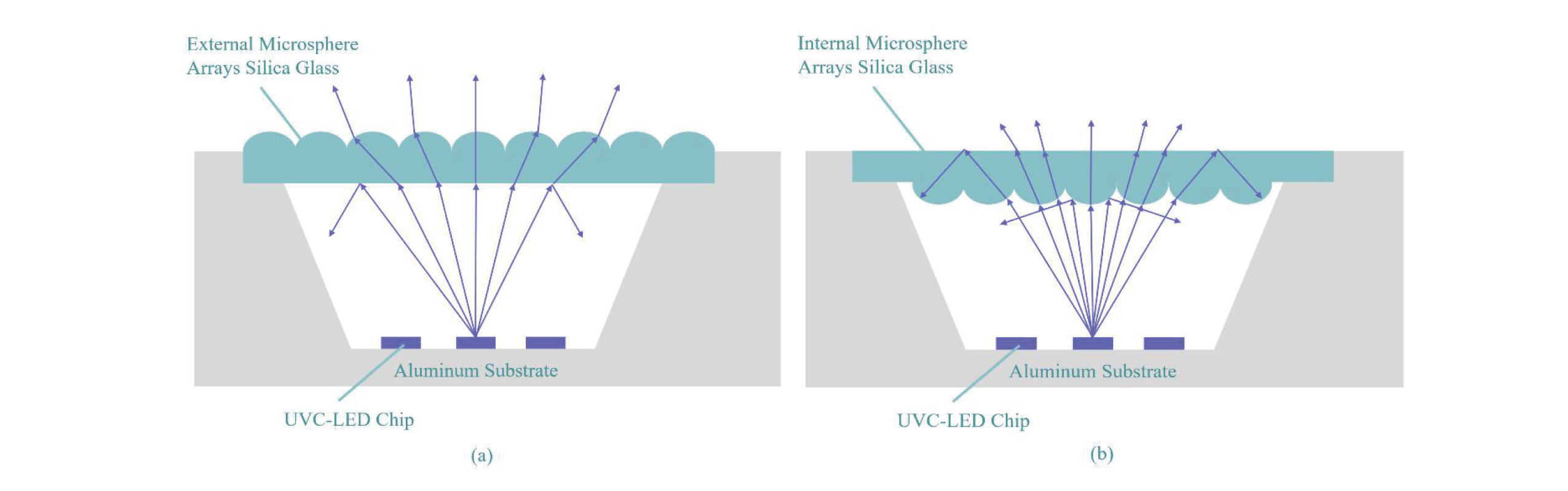

When SMT was first developed, vapor phase soldering was the preferred reflow soldering technique because of its excellent heat transfer capability. vPS is not a newly developed soldering method; it was invented in the 1970s. Since then, the process and equipment have improved. In the past, VPS used hazardous chemicals as heat transfer gases, but with the introduction of Galden fluid (i.e., perfluoropolyether, PFPE), which is also considered a non-hazardous, inert material that is non-corrosive, non-toxic, and non-flammable, VPS is now recognized as an environmentally friendly reflow soldering solution that is also highly efficient from the standpoint of energy consumption, and the chemicals used (e.g., perfluoropolyether) are not as hazardous as they could be. and the chemicals used (Galden) are harmless and environmentally friendly [40].

Unique to the VPS method is the use of vapor phase encapsulation of a special heat transfer fluid to complete the soldering of printed circuit boards (PCBs). The heat generation and transfer of the reflow process is accomplished through the latent heat of the condensate of this fluid. The main advantages of this method are the elimination of overheating, the prevention of shadowing effects (especially in large components), and the limitation of the incidence of voids in solder joints [41].

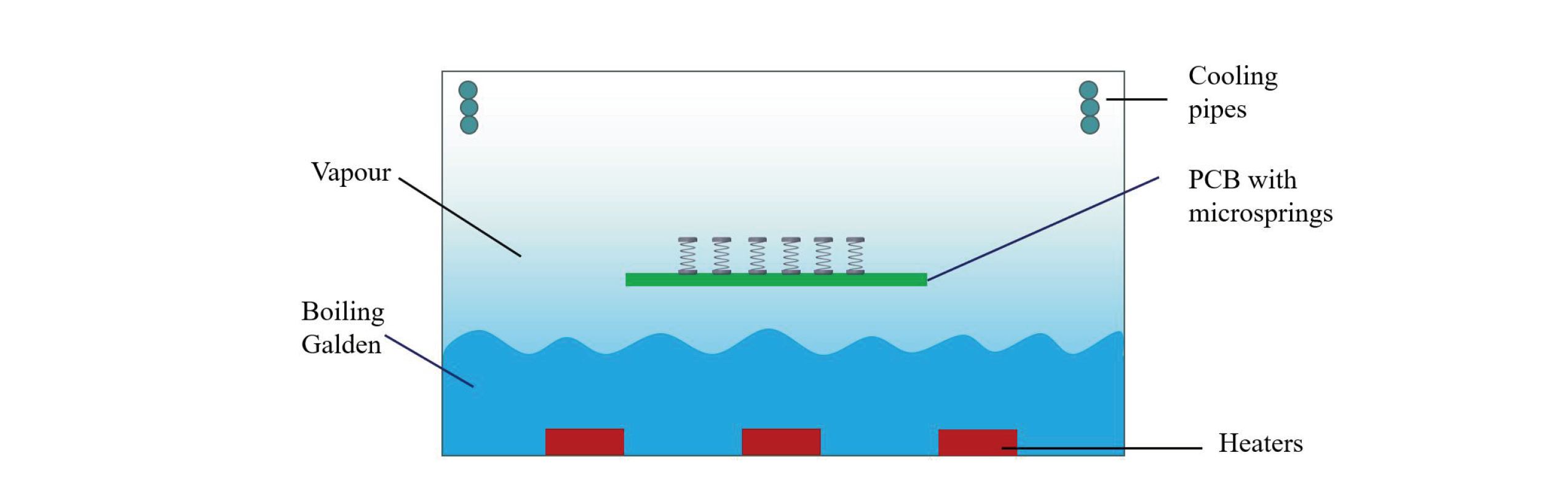

Today's vapor phase welding uses an oxygen-free environment and eliminates the possibility of overheating and vacuum application, a method that ensures higher quality joints and minimizes voids within the solder [42]. Vacuum vapor phase welding is accomplished using the principle of condensation heat transfer. The first step is to place the prepared component in the oven and then fill the bottom with a vapor liquid. At this point, the heater starts working and the water vapor liquid can be found evaporating and rising. Until the water vapor comes into contact with the cold PCB components and the cooling tubes, a lot of water vapor is produced, which is the phenomenon of condensation. The solder melts because of the release of latent heat. A schematic diagram of vacuum vapor phase soldering is shown in Figure 6 [43].

Figure 6

The schematic diagram of vacuum vapor phase soldering

To solve the cavitation problem, research scholars have conducted numerical simulation studies to investigate the heat and mass transfer processes in vacuum vapor phase welding systems during the pumping process. The results of the study show that higher heat transfer rates can be produced in an oxygen-free welding atmosphere. Vacuum welding with low vapor pressure/concentration can reduce the number of pores in the welded joints [44]. The effect of decreasing vapor concentration on welded joints under different oven settings was investigated by a three-dimensional numerical flow model based on the Reynolds-averaged Navier-Stokes equations and the standard k-e turbulence method. It was found that vapor extraction has a significant effect on the heat transfer process in the welding chamber, which may lead to premature solidification of the welded joints and reduce the efficiency of void removal. Therefore, proper adjustment of oven settings is required to minimize heat loss during the extraction process and to improve the efficiency of void removal [44].

Some research scholars have also found that the right amount of solder paste is also one of the keys to preventing the formation of voids Increasing the amount of flux in the solder paste by the right amount, especially the flux with higher activity, can significantly reduce the incidence of voids. They chose two fluxes (NC559-TPF, TSF-6516, and two solder pastes (leaded solder paste and lead-free solder paste). The amount of flux added was 0 mL, 0.4 mL, and 0.8 mL, and all other preparation conditions were the same for all combinations and were within the recommended range of the manufacturer's documentation X-rays were used to detect and analyze the distribution and number of voids in the solder layer [45]; meanwhile, a researcher used five fluxes for the study based on theirs, and three of them were gel-based fluxes (NC559, MTV- 125R, TSF-6516), and two of them were liquid-based fluxes (Topnik G-5, JBC FL-15), and observations using the same method proved that the fluxes could reduce the number of voids [46].

Subsequently, some researchers and scholars have used transient thermal simulation methods, by simulating the temperature change of the specimen in the gas-phase welding process, so as to derive the optimized gas-phase welding temperature profile, the optimized gas-phase welding temperature profile and the welding process parameters and under vacuum conditions using X-ray inspection, the results found that there is no cavity in the weld, the weld consistency of the weld is good, and meet the high-quality standards of welding to improve the quality of the assembly of the product [47].

In summary, by appropriately setting the vacuum vapor phase welding technique, increasing the amount of flux in the right amount, and adopting an optimized vapor phase welding temperature profile, the void formation rate can be effectively reduced and the quality of the joint can be improved.

4. Deep UV LED Application Market

Deep UV LEDs (UVC LEDs) are LEDs that operate at wavelengths in the range of 200 to 280 nm. They can emit high-energy deep UV radiation, which has a strong bactericidal and inactivating effect on bacteria, viruses ,and other microorganisms. The following is the application history of deep UV LEDs [48]:

Sterilization of air, water, and surfaces remains a prominent challenge in addressing current crises, combating future epidemics ,and improving overall health [49]. Water and air are the most efficient media for bacteria dispersal, and the ability to reduce bacterial levels is critical for safe drinking for millions of people worldwide [50]. Deep UV LEDs are widely used in water and air purification systems. They are used to kill bacteria, viruses, and other microorganisms to provide cleaner water and air [51].DUV-LEDs are the key enabling technology for innovative disinfection systems that promise to be miniaturized, easily modulated, and not based on contaminant low-pressure mercury lamps as shown in Figure 7 which shows a first-generation stainless steel DUV LED water disinfection chamber[52].

Figure 7

First Generation Stainless Steel DUV LED Water Disinfection Chamber. Adapted from IUVA 2012“Integration of Deep Ultraviolet Light Emitting Diode Technology into Point-of-Use Drinking Water

Deep UV LEDs are also used in medical devices for disinfection and sterilization. They can be used to clean surgical instruments, medical supplies, and hospital rooms to reduce the risk of cross-infection[53]. Since a single chip has some difficulty in achieving the UV intensity for the desired application, this needs to be accomplished through multi-chip integrated packaging. In order to be able to bring UV LEDs up to the standard for sterilization applications, chip-on-board (COB) is a proven technology that allows multiple chips to be packaged directly onto a single substrate, thus allowing for better use of UV LEDs in sterilization and virucidal applications [54].

In the context of food safety and hygiene, deep UV LEDs are used in food processing and storage to sterilize and maintain the freshness of food. They can be used to kill bacteria, molds, and other microorganisms, preventing food spoilage and spreading disease [55];

In the field of cosmetics and personal care products, deep UV LEDs are used in cosmetics and personal care products to kill bacteria and fungi, thus keeping the products hygienic and safe;

In the field of hospital and laboratory environments, deep UV LEDs are used in hospital and laboratory environments to provide cleaner air and surfaces [56]. They can effectively kill bacteria and viruses and prevent the spread of infections. For example, the global spread of novel coronavirus disease (COVID-19) infection in 2019 raised concerns about SARS-CoV-2 prevention and control. A machine that kills the virus for a short period of time reduces the chance of spreading the infection through aerosols and contact [57]. Another study found that 222 nm AlGaN deep UV LEDs were significantly more efficient for SARS-2 (COVID-19) disinfection [58]. Thus the fabrication of deep UV light-emitting diodes has a great role in stopping viruses from entering the air, for example [59].

There are many reasons to use DUV LEDs for disinfection. On the one hand, DUV LED disinfection is stronger than chlorine disinfection, which produces harmful substances. On the other hand, traditional mercury lamps are fragile, heavy, and contain toxic chemicals that have a significant impact on the environment. The final reason is that DUV LEDs are a good choice for developing countries that lack clean water and need to purify water to prevent the spreading of infectious diseases. [60].

As the technology of deep UV LEDs continues to advance and the cost decreases, their application areas will be further expanded. In the future, DUV LEDs are expected to play a more important role in the fields of medicine, health, and environmental protection. Although the efficiency of DUV LEDs still needs to be improved, they have been widely used in industry and various sterilization devices.

5. Conclusion

Research on deep ultraviolet LEDs began in the early 21st century, but there are still technical difficulties in packaging, and the efficiency of the prepared LEDs is low. In the 2010s, the packaging technology was gradually improved, the luminous efficiency and stability of deep ultraviolet LEDs were improved, and the application field began to expand. In 2017, deep ultraviolet LED packaging technology further breakthroughs, and high-efficiency, high-reliability products began mass production. After 2021, the market size of deep ultraviolet LEDs will reach billions of dollars, mainly used in disinfection, water quality testing, fluorescent light sources ,and other fields.

In recent years, the research of deep ultraviolet LED packaging has achieved satisfactory results. Specifically, the researchers have made important advances in substrate selection. The current common alumina ceramic substrate will gradually develop into a higher level of silicon substrate, which can improve the heat dissipation performance and improve the working effect of LED. At the same time, the packaging structure is also constantly innovative. For example, the introduction of liquid packaging structures and the addition of reflectors and other technologies can improve the reflectivity of the light, thereby improving the brightness and efficiency of the LED.

In addition, more in-depth research has been carried out on the application of deep ultraviolet LEDs, and they have been widely used in the market. These LEDs play an important role in water and air purification, medical devices, food safety and hygiene, cosmetics, and personal care products, hospital and laboratory environments, and wastewater treatment.

However, we cannot ignore that deep UV LED packaging still faces some problems that need to be solved. In particular, how to avoid the formation of voids in the packaging process requires continuous improvement of the process. The formation of voids may affect the brightness and stability of LEDs, so process improvements are crucial.

In short, with the continuous development and improvement of deep ultraviolet LED packaging technology, it is expected that there will be better application prospects in the future. However, further problems in the packaging process need to be solved to achieve the wider application of deep UV LEDs in the market through continuous process improvement and research.

Funding Support

Key R&D Program of Jiangsu Province (Grant No. BE2023048)

Ethical Statement

This study does not contain any studies with human or animal subjects performed by any of the authors.

Conflicts of Interest

The authors declare that they have no conflicts of interest to this work.

Data Availability Statement

Data are available from the corresponding author upon reasonable request.

Author Contribution Statement

Jichen Shen: Conceptualization, Methodology, Formal analysis, Investigation, Resources, Data curation, Writing - original draft, Visualization. Tianqi Wu: Software. Jun Zou: Writing - review & editing, Supervision. Peng Wu: Validation. Yitao Liao: Project administration.

References

[1] Lin, S. H., Tseng, M. C., Peng, K. W., Lai, S., Shen, M. C., Horng, R. H., ... & Chen, Z. (2021). Enhanced external quantum efficiencies of AlGaN-based deep-UV LEDs using reflective passivation layer. Optics Express, 29(23), 37835-37844.

[2] Hirayama, H. , Fujikawa, S. , & Kamata, N. (2015). Recent progress in algan‐based deep‐uv leds. Electronics and Communications in Japan, 98(5), 1-8.

[3] Nagai, S., Yamada, K., Hirano, A., Ippommatsu, M., Ito, M., Morishima, N., ... & Akasaki, I. (2016). Development of highly durable deep-ultraviolet AlGaN-based LED multichip array with hemispherical encapsulated structures using a selected resin through a detailed feasibility study. Japanese Journal of Applied Physics, 55(8), 082101.

[4] Kaepplinger, I., Taeschner, R., Mitrenga, D., Karolewski, D., Li, L., Meier, C., ... & Ortlepp, T. (2019). An innovative Si package for high-performance UV LEDs. Light-Emitting Devices, Materials, and Applications, 10940, 35-45.

[5] Ye, Z. T., Wei, L., Tien, C. H., & Pan, S. M. (2022). Enhancement of the light extraction characteristics and wide-angle emissive behavior of deep-ultraviolet flip-chip light-emitting diodes by using optimized optical films. Optics Express, 30(8), 13447-13458.

[6] Cengiz, C., Azarifar, M., & Arik, M. (2022). A critical review on the junction temperature measurement of light emitting diodes. Micromachines, 13(10), 1615.

[7] Nagasawa, Y., & Hirano, A. (2019). Review of encapsulation materials for AlGaN-based deep-ultraviolet light-emitting diodes. Photonics Research, 7(8), B55-B65.

[8] Lu, C. C., Wang, C. P., Liu, C. Y., & Hsu, C. P. (2016). The efficiency and reliability improvement by utilizing quartz airtight packaging of UVC LEDs. IEEE Transactions on Electron Devices, 63(8), 3143-3146.

[9] Li, W., Tang, L., Yang, Y., Zhang, Z., Li, G., Feng, M., ... & Sun, Q. (2023). Influence of thin fluorine resin film on DUV LED packaging devices. Applied Sciences, 13(11), 6536.

[10] Yamada, K., Furusawa, Y., Nagai, S., Hirano, A., Ippommatsu, M., Aosaki, K., ... & Akasaki, I. (2014). Development of underfilling and encapsulation for deep-ultraviolet LEDs. Applied Physics Express, 8(1), 012101.

[11] Peng, Y., Guo, X., Liang, R., Cheng, H., & Chen, M. (2017). Enhanced light extraction from DUV-LEDs by AlN-doped fluoropolymer encapsulation. IEEE Photonics Technology Letters, 29(14), 1151-1154.

[12] Lin, H., Huang, H., Wan, C., Xie, Z., & Wang, H. (2023). Enhancement of Radiation Efficiency for DUV-LEDs by AlN-Doped Silicone Layer Filled Chip-Side. IEEE Photonics Technology Letters, 35(17), 939-942.

[13] Yamada, K., Nagasawa, Y., Nagai, S., Hirano, A., Ippommatsu, M., Aosaki, K., ... & Akasaki, I. (2018). Study on the Main‐Chain Structure of Amorphous Fluorine Resins for Encapsulating AlGaN‐Based DUV‐LEDs. physica status solidi

(a), 215(10), 1700525.

[14] Wang, L., Yang, D., Wang, X., Yang, Z., & Cai, M. (2018). Light extraction efficiency enhancement of 265nm UVC-LED with Micro-array structure. In 2018 19th International Conference on Electronic Packaging Technology (ICEPT), 823-827.

[15] Li, Z., Li, J., Deng, Z., Qiu, Y., Li, J., Yuan, Y., ... & Ding, X. (2022). Solid–Liquid Hybrid‐State Organic Lens for Highly Efficient Deep Ultraviolet Light‐Emitting Diodes. Advanced Photonics Research, 3(5), 2100211.

[16] Ates, S., Yurtseven, M. B., & Onaygil, S. (2019). Design of a chip on board (COB) LED based industrial luminaire with thrmal simulations. Light & Engineering, 27(2).

[17] Xia, Z., Liang, S., Li, B., Wang, F., & Zhang, D. (2021). Influence on temperature distribution of COB deep UV LED due to different packaging density and substrate type. Optik, 231, 166392.

[18] Chiba, H., Suzuki, Y., Yasuda, Y., Kumagai, M., Koyama, T., & Tanaka, S. (2021). Development of silicon wafer packaging technology for deep UV LED. Electrical Engineering in Japan, 214(1), 62-68.

[19] Chiba, H., Suzuki, Y., Yasuda, Y., Gong, T., & Tanaka, S. (2022). DUV-LED packaging using high density TSV in silicon cavity and laser-glass-frit-bonded UV transmitting glass cap. Sensors and Actuators A: Physical, 344, 113700.

[20] Chiba, H., Suzuki, Y., Yasuda, Y., Gong, T., & Tanaka, S. (2021). High Light Power Density DUV-LED Packaging Using High Density TSV in Silicon Cavity and Laser-Glass-Frit-Bonded Glass Cap. In 2021 21st International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), 1162-1165.

[21] Chiba, H., Suzuki, Y., Yasuda, Y., Kumagai, M., Koyama, T., & Tanaka, S. (2020). Ultracompact silicon wafer packaging of deep UV LED with excellent cooling performance and light utilization efficiency. In 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS) (pp. 1310-1313). IEEE.

[22] Liu, J., Liu, J., Li, S., Cheng, H., Lei, Z., Peng, Y., & Chen, M. (2021). Deep-ultraviolet LEDs with all-inorganic and hermetic packaging by 3D ceramic substrate. IEEE Photonics Technology Letters, 33(4), 205-208.

[23] Tan, L., Liu, P., She, C., Xu, P., Yan, L., & Quan, H. (2021). Research on heat dissipation of multi-chip LED filament package. Micromachines, 13(1), 77.

[24] Khan, A., Kneissl, M., & Amano, H. (2023). UV/DUV light emitters. Applied Physics Letters, 123(12).

[25] Maeda, N., Jo, M., & Hirayama, H. (2018). Improving the Light‐Extraction Efficiency of AlGaN DUV‐LEDs by Using a Superlattice Hole Spreading Layer and an Al Reflector. physica status solidi (a), 215(8), 1700436.

[26] Chang, J. Y., Liou, B. T., Huang, M. F., Shih, Y. H., Chen, F. M., & Kuo, Y. K. (2019). High-efficiency deep-ultraviolet light-emitting diodes with efficient carrier confinement and high light extraction. IEEE Transactions on Electron

Devices, 66(2), 976-982.

[27] Bang, Y. T., & Moon, C. H. (2013). Enhancement of upward thermal dissipation in a 16-Chip LED package using ceramic barrier ribs. Electronic Materials Letters, 9, 1-5.

[28] Kang, C. Y., Lin, C. H., Wu, T., Lee, P. T., Chen, Z., & Kuo, H. C. (2019). A novel liquid packaging structure of deep-ultraviolet light-emitting diodes to enhance the light-extraction efficiency. Crystals, 9(4), 203.

[29] Xu, H., Long, H., Sheikhi, M., Li, L., Guo, W., Dai, J., ... & Ye, J. (2019). Strain modulated nanostructure patterned AlGaN-based deep ultraviolet multiple-quantum-wells for polarization control and light extraction efficiency

enhancement. Nanotechnology, 30(43), 435202.

[30] Zheng, Z., Chen, Q., Dai, J., Wang, A., Liang, R., Zhang, Y., ... & Li, X. (2021). Enhanced light extraction efficiency via double nano-pattern arrays for high-efficiency deep UV LEDs. Optics & Laser Technology, 143, 107360.

[31] Liu, X., Mou, Y., Wang, H., Liang, R., Wang, X., Peng, Y., & Chen, M. (2018). Enhanced light extraction of deep ultraviolet light-emitting diodes by using optimized aluminum reflector. Applied optics, 57(25), 7325-7328.

[32] Zhong, Z., Zheng, X., Li, J., Zheng, J., Zang, Y., Lin, W., & Kang, J. (2019). Fabrication of High‐Voltage Flip Chip Deep Ultraviolet Light‐Emitting Diodes Using an Inclined Sidewalls Structure. physica status solidi (a), 216(16), 1900059.

[33] Zhang, J., Chang, L., Zheng, Y., Chu, C., Tian, K., Fan, C., ... & Zhang, Z. H. (2020). Integrating remote reflector and air cavity into inclined sidewalls to enhance the light extraction efficiency for AlGaN-based DUV LEDs. Optics

Express, 28(11), 17035-17046.

[34] Qiu, J., Peng, Y., Min, X., Wang, X., & Chen, M. (2021). Enhanced light extraction of DUV LEDs by using a quartz lens with three-dimensional structure. IEEE Photonics Technology Letters, 33(24), 1403-1406.

[35] Liang, R., Dai, J., Xu, L., He, J., Wang, S., Peng, Y., ... & Chen, C. (2018). High light extraction efficiency of deep ultraviolet LEDs enhanced using nanolens arrays. IEEE transactions on electron devices, 65(6), 2498-2503.

[36] Steiner, F., Wirth, V., & Hirman, M. (2019). Relationship of soldering profile, voids formation and strength of soldered joints. In 2019 42nd International Spring Seminar on Electronics Technology (ISSE), 1-6.

[37] Otiaba, K. C., Bhatti, R. S., Ekere, N. N., Mallik, S., Alam, M. O., Amalu, E. H., & Ekpu, M. (2012). Numerical study on thermal impacts of different void patterns on performance of chip-scale packaged power device. Microelectronics Reliability, 52(7), 1409-1419.

[38] Razeeb, K. M., Dalton, E., Cross, G. L. W., & Robinson, A. J. (2018). Present and future thermal interface materials for electronic devices. International Materials Reviews, 63(1), 1-21.

[39] Okereke, M. I., & Ling, Y. (2018). A computational investigation of the effect of three-dimensional void morphology on the thermal resistance of solder thermal interface materials. Applied Thermal Engineering, 142, 346-360.

[40] Illés, B., Géczy, A., Medgyes, B., & Harsányi, G. (2018). Vapour phase soldering (VPS) technology: a review. Soldering & Surface Mount Technology, 31(3), 146-156.

[41] Géczy, A., Bozsóki, I., & Illés, B. (2018). Modelling approaches of vapour phase reflow soldering. In 2018 7th Electronic System-Integration Technology Conference (ESTC), 1-6.

[42] Alaya, M. A., Gál, L., Hurtony, T., Medgyes, B., Straubinger, D., Tareq, A. M., ... & Géczy, A. (2019). Wetting of different lead free solder alloys during vapour phase soldering. In 2019 42nd International Spring Seminar on Electronics Technology (ISSE), 1-6.

[43] Li, X., & Wu, P. (2024). Numerical investigation of solder joint shape for micro-spring package during vacuum vapor phase soldering. Microelectronics Reliability, 155, 115359.

[44] Illés, B., Skwarek, A., Géczy, A., Jakab, L., Bušek, D., & Dušek, K. (2018). Effect of the vapour concentration decrease on the solder joints temperature in a vacuum vapour phase soldering system. Soldering & Surface Mount Technology, 30(2),

66- 73.

[45] Zhai, X., Chen, Y., Li, Y., Zou, J., Shi, M., Yang, B., ... & Su, X. (2021). Research on the mechanical and performance effects of flux on solder layer interface voids. Journal of Electronic Materials, 50(12), 6629-6638.

[46] Bušek, D., Dušek, K., Růžička, D., Plaček, M., Mach, P., Urbánek, J., & Starý, J. (2016). Flux effect on void quantity and size in soldered joints. Microelectronics Reliability, 60, 135-140.

[47] Yang, H., & Jing, Z. (2021). Research on thermal simulation improving the components’ soldering quality in electronic module. In Journal of Physics: Conference Series, 1965(1), 012020.

[48] Shatalov, M., Lunev, A., Hu, X., Bilenko, O., Gaska, I., Sun, W., ... & Shur, M. (2012). Performance and applications of deep UV LED. International Journal of High Speed Electronics and Systems, 21(01), 1250011.

[49] Zollner, C. J., DenBaars, S. P., Speck, J. S., & Nakamura, S. (2021). Germicidal ultraviolet LEDs: A review of applications and semiconductor technologies. Semiconductor Science and Technology, 36(12), 123001.

[50] Matsumoto, T., Kikojima, R., Fukuoka, T., Tatsuno, I., & Hasegawa, T. (2019). Total internal reflection of deep-ultraviolet light in a water waveguide and its application to water disinfection technologies. Water, 11(2), 294.

[51] Manley, P., Walde, S., Hagedorn, S., Hammerschmidt, M., Burger, S., & Becker, C. (2020). Nanopatterned sapphire substrates in deep-UV LEDs: is there an optical benefit?. Optics Express, 28(3), 3619-3635.

[52] Gaska, I., Bilenko, O., Smetona, S., Bilenko, Y., Gaska, R., & Shur, M. (2014). Deep UV LEDs for public health applications. International Journal of High Speed Electronics and Systems, 23(03n04), 1450018.

[53] Bando, H. (2021). Some Measures for COVID-19 Including Deep Ultraviolet Light-Emitting Diode (DUV-LED), Gc protein-derived Macrophage-Activating Factor (Gcmaf), and 5-Aminolevulinic Acid (5-ALA). Asploro Journal of Biomedical and Clinical Case Reports, 4(2), 110.

[54] Liu, P., She, C., Tan, L., Xu, P., & Yan, L. (2022). Development of LED package heat dissipation

research. Micromachines, 13(2), 229.

[55] Kneissl, M., Seong, T. Y., Han, J., & Amano, H. (2019). The emergence and prospects of deep-ultraviolet light-emitting diode technologies. nature photonics, 13(4), 233-244.

[56] Nagasawa, Y., & Hirano, A. (2018). A review of AlGaN-based deep-ultraviolet light-emitting diodes on sapphire. Applied Sciences, 8(8), 1264.

[57] Inagaki, H., Saito, A., Sugiyama, H., Okabayashi, T., & Fujimoto, S. (2020). Rapid inactivation of SARS-CoV-2 with deep-UV LED irradiation. Emerging Microbes & Infections, 9(1), 1744-1747.

[58] Jamil, T., Usman, M., Jamal, H. U., & Khan, S. (2021). Marked efficiency enhancement of 222 nm AlGaN-based deep-UV LEDs for disinfection of SARS-2 (Covid-19). In 2021 International Conference on Numerical Simulation of Optoelectronic Devices (NUSOD), 67-68.

[59] Shimoda, H., Matsuda, J., Iwasaki, T., & Hayasaka, D. (2021). Efficacy of 265-nm ultraviolet light in inactivating infectious SARS-CoV-2. Journal of Photochemistry and Photobiology, 7, 100050.

[60] Trivellin, N., Monti, D., De Santi, C., Buffolo, M., Meneghesso, G., Zanoni, E., & Meneghini, M. (2018). Current induced degradation study on state of the art DUV LEDs. Microelectronics Reliability, 88, 868-872.

How to Cite

Shen, J., Wu, T., Zou, J., Wu, P., & Liao, Y. (2024). Development of Deep Ultraviolet LED Packaging. Journal of Optics and Photonics Research. https://doi.org/10.47852/bonviewJOPR42022714